Introduction

Stainless steel sheets have become an integral part of various industries, including construction, automotive, and aerospace. Known for their durability, corrosion resistance, and aesthetic appeal, these sheets undergo a meticulous manufacturing process. In this article, we will delve into the detailed process of manufacturing stainless steel sheets, from the raw materials to the finished product.

Raw Materials

Stainless steel sheets, renowned for their strength, corrosion resistance, and aesthetic appeal, are manufactured from carefully selected raw materials. In this section, we will explore the primary ingredients used in the production of stainless steel sheets and their significance in the manufacturing process.

Iron Ore:

Iron ore is the fundamental raw material in stainless steel production. It serves as the major source of iron, which provides the structural base and strength to the stainless steel sheets. The quality and composition of the iron ore contribute significantly to the final properties of the stainless steel.

Chromium:

Chromium is a vital alloying element in stainless steel production, responsible for its superior corrosion resistance. The addition of chromium forms a passive oxide layer on the surface of the stainless steel, preventing it from rusting and making it resistant to various corrosive environments.

Nickel:

Nickel is another crucial alloying element in stainless steel manufacturing. It enhances the mechanical properties of stainless steel, such as strength, toughness, and ductility. Additionally, nickel improves the corrosion resistance of stainless steel, particularly in acidic environments.

Alloying Elements:

Stainless steel sheets often incorporate other alloying elements to impart specific properties. Molybdenum, for example, enhances the resistance to pitting and crevice corrosion, while titanium improves weldability and stability during high-temperature processes. Other elements, such as manganese, nitrogen, and silicon, may be added to achieve desired characteristics in terms of strength, formability, and workability.

Scrap Metal:

In addition to the primary raw materials mentioned above, stainless steel production frequently involves the utilization of recycled or scrap metal. By recycling and incorporating scrap steel, the industry promotes sustainability and reduces the demand for virgin raw materials. The composition analysis of the scrap metal is crucial to maintaining the desired quality and specifications of stainless steel sheets.X

Melting and Casting:

Melting is the initial step in producing stainless steel sheets, involving the liquefaction of raw materials. The process includes:

Electric Arc Furnace (EAF):

Modern stainless steel production typically employs an electric arc furnace. Scrap metal, along with carefully measured quantities of iron ore, chromium, nickel, and other alloys, is charged into the EAF. By generating intense heat through electric arcs reaching temperatures of 1600-1800 degrees Celsius, the raw materials melt and form a homogenous molten metal.

Ladle Furnace:

Following the initial melting in the electric arc furnace, the molten metal is often transferred to a ladle furnace. This furnace allows for refining and adjustment of the molten metal’s chemical composition and temperature, ensuring desired quality and properties of the stainless steel are achieved.

Casting is the subsequent process where the molten metal is transformed into slabs or billets, which are further processed into stainless steel sheets. The casting process involves:

Continuous Casting:

Continuous casting is a widely used technique in stainless steel production. The molten metal is poured into a water-cooled copper mold, which rapidly solidifies the outer layer, forming a solid shell. The partially solidified metal is then continuously withdrawn through rollers, resulting in long slabs or billets with consistent cross-sections.

Ingot Casting:

Ingot casting is an alternative approach primarily used for specialized stainless steel alloys or smaller production quantities. Here, molten metal is poured into individual molds, called ingot molds, which are uniquely shaped. The metal solidifies within these molds, forming solid metal ingots that are further processed into stainless steel sheets.

Throughout the melting and casting process, strict quality control measures are implemented to ensure the production of SS sheets adhering to the desired specifications. These measures include:

Chemical Analysis:

At regular intervals, samples of the molten metal are taken and subjected to chemical analysis. This analysis verifies the composition, ensuring it meets the required standards and maintaining consistency and quality in the stainless steel sheets produced.

Non-Destructive Testing:

Various non-destructive testing methods, like ultrasonic testing or electromagnetic testing, are employed to identify potential defects or discontinuities in the cast slabs or billets. Early detection enables corrective actions before further processing.

Visual Inspection:

Operators and inspectors visually examine the cast products to detect surface irregularities, cracks, or any visible defects. Any anomalies identified are flagged and addressed promptly.

Hot Rolling:

Once the ingots have solidified, they undergo hot rolling, a process that reduces the ingots’ thickness and changes their mechanical properties. The ingots are heated and passed through a series of rollers to gradually reduce their thickness, ultimately forming thin slabs known as hot-rolled coils. The hot rolling process improves the metal’s grain structure and removes any internal defects.

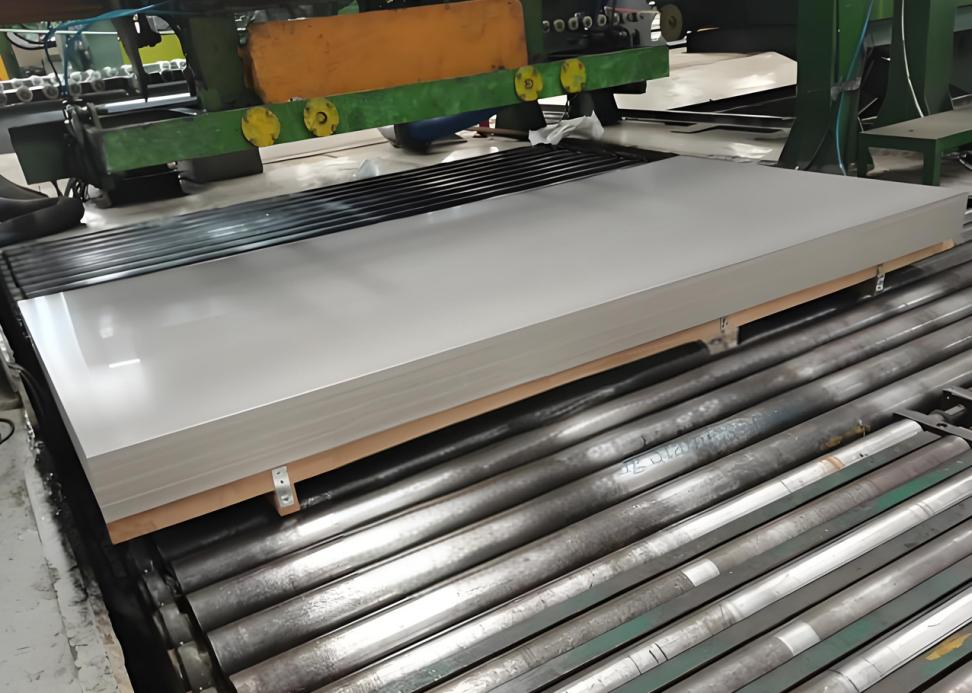

Cold Rolling:

After the hot rolling process, the hot-rolled coils are further processed through cold rolling. This stage involves passing the coils through a set of rollers at ambient temperature. The cold rolling process refines the surface finish of the metal, adjusts its thickness, and enhances its mechanical strength. The coils are repeatedly passed through the rollers until the desired thickness is achieved.

Annealing and Pickling:

To improve the stainless steel sheet’s ductility and corrosion resistance, the cold-rolled coils undergo an annealing process. Annealing involves heating the coils to high temperatures and then gradually cooling them. This process recrystallizes the metal’s structure, reducing its hardness and making it more workable.

Following annealing, the coils go through a pickling stage. Pickling removes any surface impurities, such as oxides and scale, by submerging the coils in a mixture of acids. This step enhances the sheet’s appearance and ensures a clean surface before further processing.

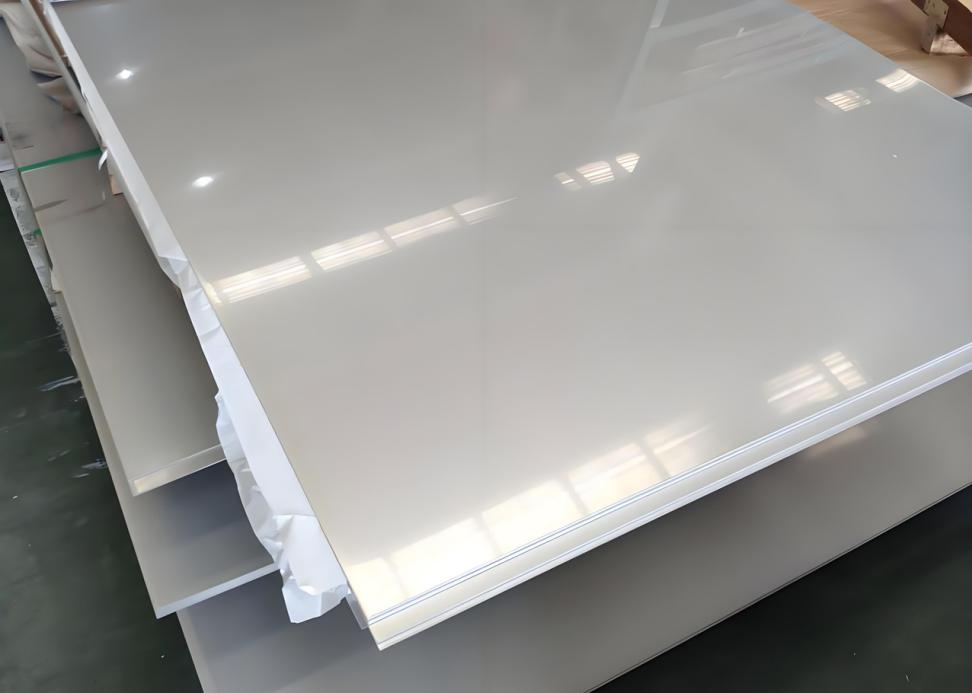

Finishing Processes:

After pickling, the stainless sheets are ready for finishing processes that enhance their appearance and performance. These processes include:

Grinding and Polishing:

The sheets may undergo grinding to achieve a smooth, uniform surface. This removes any minor imperfections and prepares the sheets for subsequent polishing. Polishing further refines the surface, resulting in a glossy and reflective finish.

Coating:

In some cases, stainless steel sheets are coated with protective films or coatings. These coatings offer additional protection against scratching and provide an extra layer of corrosion resistance.

Cutting and Shearing:

At this stage, the stainless steel sheets are cut and sheared into desired sizes and shapes. Advanced cutting techniques such as laser cutting or waterjet cutting may be utilized to achieve precise dimensions.

Quality Control:

Throughout the manufacturing process, strict quality control measures are implemented to ensure the stainless steel sheets meet industry standards. Various tests are conducted, including dimensional checks, mechanical property assessments, and corrosion resistance evaluations. Only sheets that pass these rigorous inspections move on to packaging and distribution.

Conclusion:

The process of manufacturing stainless steel sheets involves several intricate steps, starting from the selection of high-quality raw materials to the final product inspection. Melting, casting, hot rolling, cold rolling, annealing, pickling, and finishing processes all contribute to the production of durable, corrosion-resistant, and visually appealing stainless steel sheets. Understanding this manufacturing journey provides a deeper appreciation for the craftsmanship and engineering behind these versatile and indispensable materials.