Introduction

Stainless steel sheets have become a ubiquitous material in various industries due to their exceptional qualities and functionality. From construction to manufacturing, stainless steel sheets offer durability, corrosion resistance, and aesthetic appeal. In this article, we will delve into the fundamental aspects of stainless steel sheets, exploring their composition, grades, finishes, and applications. By understanding these basics, you can make informed decisions when it comes to selecting and utilizing stainless steel sheets in your projects.

Composition and Properties of Stainless Steel Sheets

Stainless steel sheets(plates) are primarily composed of iron and a minimum of 10.5% chromium, giving them their notable corrosion resistance. However, additional elements such as nickel, molybdenum, and titanium can be added to enhance specific properties. The chromium content forms a passive oxide layer on the surface of the sheet, preventing oxidation, rusting, and staining.

Different grades of stainless steel sheets offer varying levels of corrosion resistance, strength, and heat resistance. The most common grades include 304, known for its general-purpose use, and 316, which is ideal for marine environments and chemical processing plants. Additionally, we will explore other variations, such as 430, which offers good mechanical properties but lower corrosion resistance.

Understanding Finishes and Surface

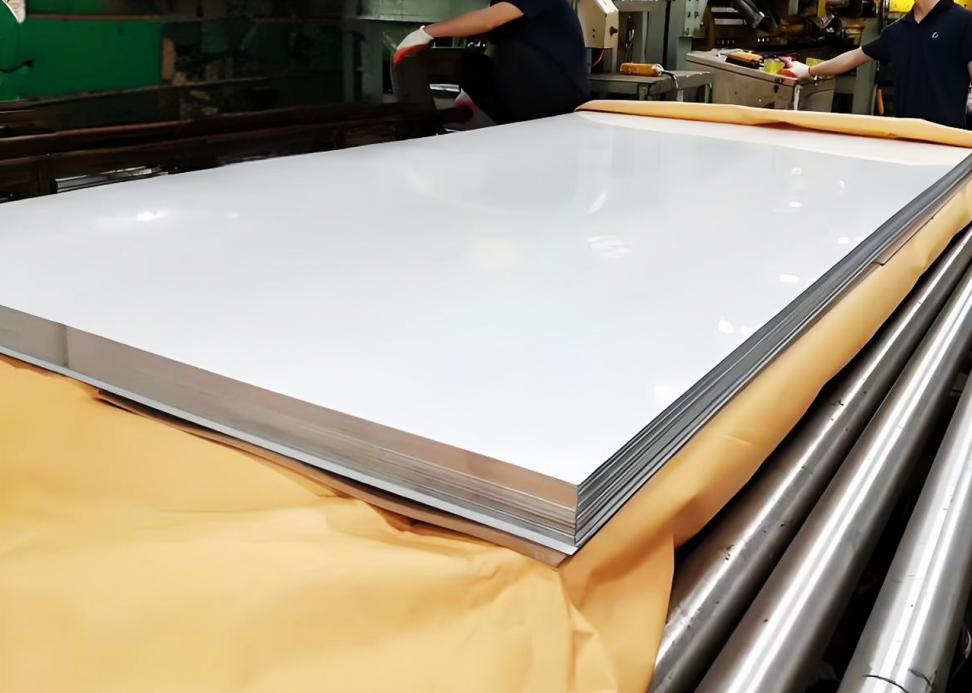

Stainless steel plates are available in a range of finishes, each providing distinct appearances and properties. One popular finish is the 2B finish, characterized by a smooth and reflective surface, making it ideal for industrial applications. Satin or brushed finishes offer a finely textured appearance achieved through brushing techniques. Alternatively, a mirror finish provides a highly reflective, mirror-like appearance perfect for decorative purposes. Additionally, embossed finishes involve creating raised patterns on the surface, offering both functionality and aesthetic interest.

2B Finish:

The 2B finish is the most common SS sheet finish. It features a smooth and reflective surface, making it suitable for a wide range of industrial applications. This finish is achieved by cold rolling the sheet and subsequently annealing and pickling it to remove any scale or impurities. The resulting surface is characterized by a consistent, unidirectional grain pattern that provides a clean and aesthetic appearance. The 2B finish offers good corrosion resistance and is easy to clean, making it a popular choice for applications such as kitchen equipment, automotive trim, and architectural components.

Satin or Brushed Finish:

Satin or brushed finishes are achieved by mechanically brushing the surface of the stainless steel sheet with abrasive material. This process creates a fine and consistent linear grain pattern on the surface. The satin finish offers a sophisticated and matte appearance, making it an excellent choice for applications in architecture, interior design, and furniture. Its ability to mask scratches and fingerprints makes it a preferred option for high-traffic areas and surfaces prone to frequent use.

Mirror Finish:

The mirror finish is a highly reflective, glossy surface that resembles a mirror. Achieving this finish involves additional polishing steps, such as buffing with fine abrasive compounds or using mechanical polishing techniques. Mirror-finished stainless steel sheets are widely used in decorative applications, such as wall cladding, signage, and ornamental pieces. They provide a visually striking and elegant appearance, adding a touch of luxury to any space.

Embossed Finish:

Embossed finishes involve imprinting raised or textured patterns on the surface of the stainless steel sheet. This process enhances both functionality and aesthetics. The embossed patterns not only provide visual interest but also serve practical purposes such as enhancing grip, reducing glare, or improving structural strength. Embossed stainless steel plates find applications in areas such as elevator panels, door skins, and decorative accents.

Other Finishes:

In addition to the commonly used finishes mentioned above, there are other specialized finishes available for specific applications. Examples include the bead blast finish, which creates a uniform and matte surface by bombarding the sheet with glass beads, and the antique finish, which replicates the weathered appearance of aged stainless steel.

It is important to note that each finish has different maintenance requirements and may offer varying degrees of resistance to scratches, corrosion, and staining. Consider the specific functional and aesthetic requirements of your project when selecting the appropriate finish for your stainless steel sheets.

By understanding the different finishes and surface textures available, you can choose stainless steel sheets that not only meet your desired aesthetic but also provide the necessary functionality for your specific application. Whether you are looking for a sleek and modern industrial finish or an elegant and decorative option, there is a stainless steel sheet finish suited for your needs. Consult with suppliers and professionals in the industry to explore the full range of finishes and make an informed decision that ensures the success of your project.

Extensive Applications of Stainless Steel Sheets

Stainless steel coils find extensive application across various industries and sectors. In the architecture and construction industry, they are commonly used for facades, handrails, interior decoration, and roofing due to their durability and aesthetic appeal. In the automotive sector, stainless steel sheets are employed for exhaust systems, trimmings, and various decorative elements that require resistance to corrosion and heat.

The food processing industry benefits greatly from stainless steel sheets as they are hygienic, easy to clean, and resistant to food acids. Kitchen equipment, appliances, and commercial refrigeration units are often constructed using stainless steel sheets to meet regulatory requirements and maintain food safety standards.

Stainless steel sheets also have a significant presence in the medical and pharmaceutical fields. Surgical instruments and medical equipment are manufactured from stainless steel due to its biocompatibility, corrosion resistance, and ease of sterilization.

Industrial applications of stainless steel sheets include chemical processing equipment, storage tanks, and heat exchangers. The ability to withstand harsh environments and corrosive chemicals makes stainless steel sheets an ideal choice.

Conclusion

In conclusion, SS plates are a versatile and reliable material used in numerous industries. Understanding their composition, various grades, finishes, and applications is crucial when seeking the right stainless steel sheet for specific projects. The corrosion resistance, durability, and aesthetic appeal offered by stainless steel sheets make them a preferred choice for architects, engineers, manufacturers, and individuals seeking long-lasting and functional solutions

By considering factors such as the environment, required corrosion resistance, and budget, one can make informed decisions regarding the appropriate grade and finish of stainless steel sheets. Consulting with professionals and suppliers in the field is advisable to ensure the best material choice for specific applications.

Remember, stainless steel sheets are not just ordinary metal sheets. They are reliable workhorses that provide both functional and visual benefits. With an understanding of the basics, you can confidently harness the power of stainless steel sheets in your projects, achieving longevity and excellence.