Stainless Steel Bars

Stainless steel bars are long metal strips with round, square, or hexagonal cross-sections. Known for their corrosion resistance, strength, and toughness, they can be processed in various ways.

Stainless steel bars are widely used in industries such as machinery, construction, automotive, medical equipment, food processing, and aerospace due to their excellent mechanical properties.

Classification and Common Brands

Classification | Definition | Features | Common Grades |

Austenitic Stainless Steel | Non-magnetic stainless steel containing chromium (usually more than 18%) and nickel (usually more than 8%). The microstructure is austenitic (face-centered cubic crystal structure) at all temperatures. Usually contains small amounts of nitrogen to enhance strength and corrosion resistance. | Excellent corrosion resistance, good mechanical properties, good weldability, non-magnetic (may be slightly magnetic after cold working). | 304, 304L, 316, 316L, 321, 310S |

Ferritic Stainless Steel | It is mainly composed of chromium (10.5-30%), with a low carbon content (usually less than 0.1%), and has a body-centered cubic crystal structure. It contains no or only a small amount of nickel and is relatively low in cost. | Good corrosion resistance, excellent oxidation resistance, magnetic, low weldability (heat treatment may be required after welding to restore properties). | 430, 409, 439, 444 |

Martensitic Stainless Steel | Contains high carbon (0.1-1.2%) and chromium (12-18%), and forms a martensitic crystal structure through quenching and tempering. Hardness and strength can be adjusted through heat treatment. | High strength and hardness, moderate corrosion resistance, adjustable mechanical properties, magnetic properties. | 410, 420, 440C, 416 |

Duplex Stainless Steel | It has both austenite and ferrite phase structures, usually containing about 50% austenite and 50% ferrite. | Excellent corrosion resistance, high strength, good toughness and ductility, magnetic properties (lower magnetic properties than pure ferritic stainless steel). | 2205, 2507, |

| Material | Definition | Features |

| 15-5ph | A precipitation hardening stainless steel containing 15% chromium and 5% nickel. | Excellent mechanical properties and good corrosion resistance. |

| 17-4ph | A precipitation hardening stainless steel containing 17% chromium and 4% nickel. | High strength, good corrosion resistance, easy to weld. |

| 303 | An austenitic stainless steel with added sulfur and selenium. | Good machinability, moderate corrosion resistance. |

| 304 | The most commonly used austenitic stainless steel contains 18% chromium and 8% nickel. | Excellent corrosion resistance, good formability and weldability. |

| 316 | An austenitic stainless steel containing 2-3% molybdenum. | Higher corrosion resistance, especially in chloride-containing environments. |

| 321 | An austenitic stainless steel with the addition of titanium. | Good resistance to intergranular corrosion. |

| 347 | An austenitic stainless steel with the addition of niobium. | Excellent resistance to intergranular corrosion. |

| 410 | A martensitic stainless steel containing 12% chromium. | Good wear resistance and strength. |

| 416 | A martensitic stainless steel with sulfur added. | Good machinability, moderate corrosion resistance. |

| 440C | A high carbon, high chromium martensitic stainless steel. | Extremely high hardness and wear resistance. |

Three Common Production Processes

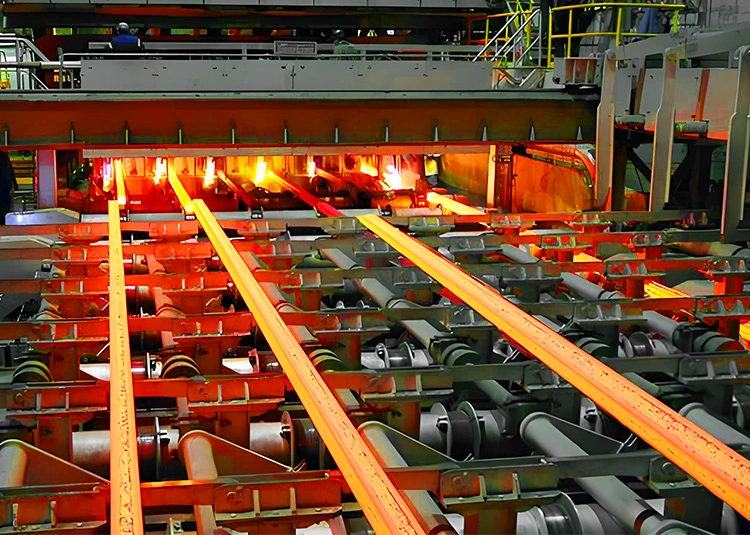

Hot Rolling

It is a metal processing method that rolls stainless steel above its recrystallization temperature to form it into bars. The recrystallization temperature is usually between 1100°C and 1300°C.

Heating : The stainless steel billet is first heated in a furnace to above the recrystallization temperature. This causes the metal’s internal structure to become softer and more plastic.

Rolling : The heated stainless steel is continuously rolled through a series of rollers. During this process, the thickness of the metal is gradually reduced and the length is increased, eventually forming a bar of the desired size and shape.

Cooling : After rolling, the stainless steel bar is cooled by air or water. The cooling rate affects the microstructure and mechanical properties of the final product.

Surface treatment : The surface after hot rolling is usually rough and may require pickling or passivation to remove the surface oxide scale and improve the surface quality.

Cold Drawing

It is a process in which stainless steel is drawn or stretched at room temperature to form a bar of the desired size and shape. Unlike hot rolling, the metal does not recrystallize during the cold drawing process.

Preparation : Before cold drawing, the raw material usually needs to be pre-treated, such as annealing or pickling, to reduce the hardening and surface defects of the material during the cold drawing process.

Drawing : Stainless steel is drawn into the desired shape and size at room temperature through a series of progressively smaller dies or orifices. The tensile force applied during the drawing process causes the metal to undergo plastic deformation.

Dimensional control : The cold drawing process can achieve high-precision dimensional control and a small tolerance range, so it is suitable for manufacturing bars that require high precision.

Surface quality : The surface of stainless steel bars after cold drawing is smooth and usually does not require further processing. They can be directly used in applications with high surface quality requirements.

Annealing

It refers to the process of heating stainless steel to a specific temperature, keeping it at that temperature for a period of time, and then slowly cooling it. The purpose of annealing is to eliminate internal stress, soften the metal, and improve the processing properties and corrosion resistance of the material.

Heating : Heat the stainless steel bar to an appropriate temperature, usually between 750°C and 950°C, depending on the type of stainless steel and the properties required.

Insulation : After being heated to the target temperature, the material is kept at that temperature for a period of time to ensure uniform temperature and promote grain growth and homogenization of the structure.

Cooling : The cooling process after annealing is usually slow to avoid new stress inside the material. The cooling method can be furnace cooling or cooling in air.

Effect : Annealing can eliminate the internal stress generated during cold working, restore the plasticity and toughness of the material, improve the processing performance and corrosion resistance of the material, and make it suitable for further processing or use.

Eliminate internal stress : Annealing can eliminate the internal stress generated by the material during processing and prevent deformation and cracking.

Improved structure : Annealing can refine the grains, make the structure uniform, and improve the mechanical properties and processing properties of the material.

Softening the material : Annealing softens the material, making it easier for subsequent processing and forming.

Improve corrosion resistance : For some stainless steels, their corrosion resistance can be improved by annealing.

Cutting Methods

Laser Cutting

Laser cutting is a process of cutting by irradiating a high-power laser beam onto the surface of stainless steel, causing it to melt, vaporize or ablate rapidly, and then blowing away the molten material through coaxial high-pressure gas.

Plasma Cutting

Plasma cutting is a method of cutting stainless steel using a high-temperature plasma arc. The plasma arc ionizes a gas into a high-temperature plasma through an electric arc to melt the metal, and then blows the molten metal away through a high-speed gas flow.

Sawing Machine Cutting

Sawing is a mechanical cutting method that uses a band saw or circular saw to cut stainless steel bars into the required size. The sawing machine is usually driven by an electric motor and the cutting is completed by the high-speed rotation or reciprocating motion of the saw blade or saw blade.

Sawing Machine Type

Band saw : uses a circular band saw blade and is suitable for cutting long bars and workpieces with larger cross-sections.

Circular saw : uses a circular saw blade and is suitable for cutting smaller diameter bars and thinner materials.

Bow saw : uses a saw blade with linear reciprocating motion, suitable for cutting bars of various sizes.

Precision and Quality

Saw cutting has high cutting accuracy and straight cuts, which is suitable for most industrial applications.

The cut surface finish is good but may require further machining to achieve a smooth surface quality.

Applications

Construction: Reinforcement bars (rebar) for concrete structures, ensuring strength and durability.

Automotive: Parts such as exhaust systems, trim, and brackets due to their corrosion resistance and aesthetic appeal.

Manufacturing: Precision components like machine shafts, gears, and tools requiring high strength and wear resistance.

Marine: Structural elements and fittings exposed to harsh environments, providing resistance to saltwater corrosion.

Aerospace: Aircraft components, including structural and engine parts, for their strength-to-weight ratio and resistance to extreme conditions.

Medical: Surgical instruments, implants, and prosthetics due to their biocompatibility and sterilizability.

FAQs

1. Can you bend stainless steel bars?

Yes, stainless steel bars can be bent. The feasibility of the bend depends on the material, diameter, and angle of the desired bend. Generally, 304 and 316 stainless steels are easier to bend, while harder grades such as 440c are more difficult to bend.

2. Calculation formula for stainless steel bars

Weight per meter = diameter + diameter * 0.0623

Example: Weight of 1 meter of 10 mm diameter bar

10*10*0.00623=0.623

3. Stainless Steel Bars Price

The price of stainless steel bars varies depending on the material, size, process and market conditions. Please contact us for the latest quote.

Want to Know More?

Try before you buy—get a sample of our high-quality stainless steel materials.