Introduction:

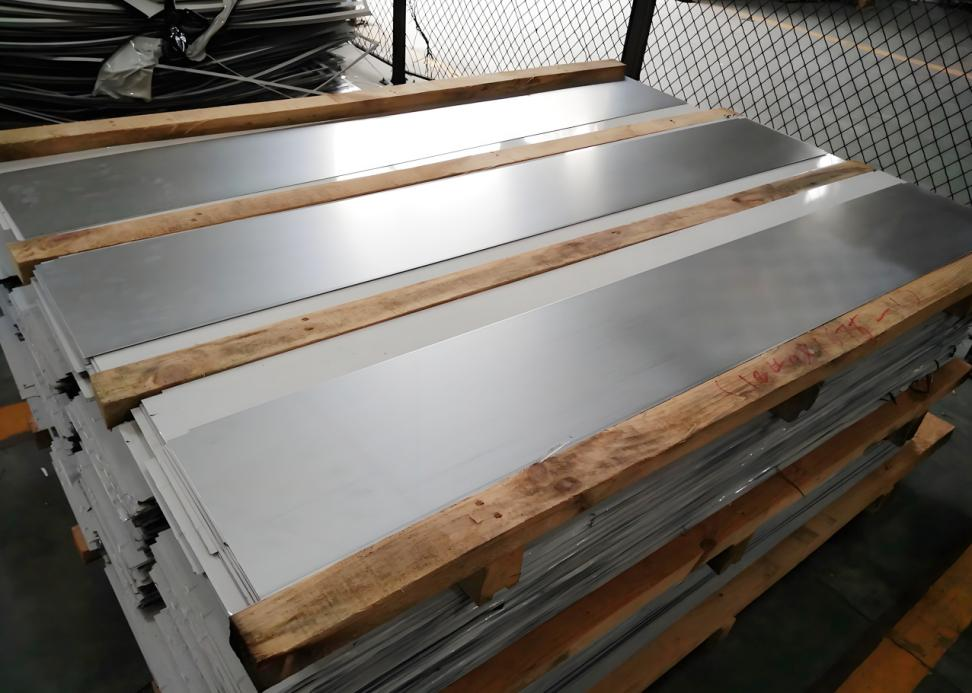

Stainless steel sheets are widely used in various industries due to their exceptional durability and versatility. However, the recycling and sustainability aspects of stainless steel often go unnoticed or underappreciated. This comprehensive article aims to provide a scientific exploration of the remarkable benefits of recycling stainless steel sheets and the significant environmental advantages associated with their reuse.

The Remarkable Benefits of Recycling Stainless Steel Sheets:

Stainless steel possesses a unique property – it can be recycled indefinitely without compromising its quality. This characteristic makes it a sustainable choice for industries and consumers alike. Let’s delve into the advantages of recycling stainless steel sheets:

Conserving Natural Resources:

Recycling stainless steel plays a crucial role in the conservation of valuable natural resources. By choosing to recycle stainless steel, we can significantly reduce the need for extracting primary metals such as iron ore and chromium. This reduction in primary metal extraction helps preserve our finite natural resources and minimizes the environmental impact caused by extensive mining operations. By opting for recycling, we take a proactive step towards sustainable resource management.

Furthermore, the conservation of natural resources through stainless steel recycling extends beyond the realm of mining. The extraction and processing of primary metals require vast amounts of energy, water, and other resources. By recycling stainless steel, we reduce the overall demand for these resources, easing the strain on ecosystems and minimizing environmental degradation associated with resource-intensive extraction processes.

Energy Savings:

One of the significant advantages of recycling stainless steel is the substantial energy savings it offers. The process of recycling stainless steel requires considerably less energy compared to the production of virgin stainless steel from primary sources. When stainless steel scrap is recycled, it is melted and reprocessed into new sheets or other stainless steel products using a fraction of the energy required for the initial production.

The energy savings achieved through stainless steel recycling contribute to the global effort in combating climate change. The production of stainless steel from raw materials releases significant amounts of greenhouse gas emissions into the atmosphere, contributing to the overall carbon footprint. By choosing recycled stainless steel, which requires less energy, we can effectively reduce carbon emissions and mitigate the environmental impact associated with traditional production methods. This energy-efficient approach to stainless steel production aligns with sustainability goals and helps create a more environmentally friendly future.

Waste Reduction:

Recycling stainless steel plates/sheets offers a substantial solution to waste reduction. Rather than allowing stainless steel sheets to end up in landfills, recycling diverts them from waste streams, leading to multiple environmental benefits.

By diverting stainless steel sheets from landfills, the strain on waste management systems is significantly reduced. Landfills are already burdened with massive amounts of waste and limited space. Through recycling, the volume of waste that would otherwise occupy landfill space is decreased, prolonging the lifespan of existing landfills and reducing the need for costly expansion or the establishment of new ones.

Moreover, the environmental impacts associated with landfilling stainless steel sheets are minimized through recycling. When stainless steel is dumped into landfills, it can take a significant amount of time to decompose, potentially releasing harmful substances into the surrounding soil and water. By recycling stainless steel sheets, these environmental hazards are mitigated, promoting a cleaner and healthier environment.

Unveiling the Recycling Process:

The recycling process for stainless steel sheets involves several scientific steps:

Collection:

In the collection stage of the stainless steel sheet recycling process, various sources are tapped to ensure a consistent supply of material. Industrial scraps, such as leftover pieces from manufacturing plants and factories, serve as a valuable source for recycling. Additionally, end-of-life products, such as old appliances or automobiles, are carefully dismantled to extract the stainless steel sheets for recycling purposes. Construction waste, including discarded structures or infrastructure, also contributes to the collection of stainless steel sheets. By utilizing these diverse sources, the recycling industry effectively replenishes the supply of stainless steel material, reducing the need for virgin resources.

Sorting and Cleaning:

Upon collection, the stainless steel sheets undergo an intricate sorting process to categorize them based on various factors. This meticulous sorting is crucial in determining the specific properties of the stainless steel, such as grade, size, and alloy type. Sophisticated technologies and experienced professionals are employed to ensure accurate classification, maximizing efficiency in the recycling process. Once sorted, the sheets proceed to a thorough cleaning stage. This cleaning process removes contaminants and surface coatings that may have accumulated during the product’s lifecycle. By eliminating these impurities, the quality of the recycled material is enhanced, paving the way for the production of high-quality stainless steel products.

Melting and Purification:

After the rigorous sorting and cleaning processes, the stainless steel sheets are ready for transformation through melting and purification. This stage involves the use of electric arc furnaces or induction furnaces, where extreme heat is applied to melt the stainless steel sheets. The intense heat effectively eliminates any remaining impurities present in the material. Through this purification process, which often involves the addition of alloys as necessary, the recycled stainless steel attains the desired composition and properties. Achieving a high level of purity ensures that the resulting recycled stainless steel is of superior quality and can meet the stringent requirements of various industries.

Production of New Products:

Once the stainless steel has been melted and purified, it is ready to be transformed into new sheets or other stainless steel products. The molten material is carefully shaped and formed through various manufacturing processes, such as rolling, cutting, and stamping. These processes enable the creation of stainless steel products with different dimensions, thicknesses, and shapes to suit specific applications. The versatility of recycled stainless steel allows for its use in a wide range of industries and products. From everyday household items like kitchen appliances and utensils to robust industrial machinery and infrastructure, the recycled stainless steel contributes to sustainable manufacturing practices while maintaining the durability and performance expected from this remarkable material.

Innovations in Sustainable Practices and Certifications:

To further enhance the sustainability of stainless steel production and recycling, manufacturers and suppliers are increasingly adopting innovative practices and obtaining certifications that emphasize environmental responsibility, such as:

Energy Efficiency:

Implementing energy-efficient technologies and processes throughout the manufacturing stages is a crucial aspect of sustainable stainless steel production. By prioritizing energy efficiency, manufacturers aim to minimize energy consumption, reduce greenhouse gas emissions, and decrease the overall carbon footprint of stainless steel production. This involves the use of advanced technologies, such as energy-efficient furnaces and machinery, optimized production processes, and smart energy management systems. By continuously monitoring energy usage, identifying areas of high consumption, and implementing energy-saving measures, companies can significantly enhance the energy efficiency of their operations. This not only helps to conserve valuable resources but also reduces operating costs and contributes to the long-term sustainability of the stainless steel industry.

Renewable Energy Integration:

To further enhance the environmental performance of stainless steel production, many manufacturers are embracing renewable energy sources as a clean and sustainable power solution. By incorporating solar, wind, or other renewable energy systems into their operations, companies can significantly reduce their reliance on fossil fuels and decrease their carbon emissions. Installing solar panels or wind turbines allows stainless steel producers to generate renewable electricity on-site, which can power their manufacturing processes and reduce the demand for energy from the grid. By transitioning to renewable energy sources, these companies contribute to the global shift towards a low-carbon economy and demonstrate their commitment to environmental stewardship.

Environmental Certifications:

Obtaining environmental certifications, such as ISO 14001, is an essential step for stainless steel manufacturers in demonstrating their commitment to sustainable practices. ISO 14001 is an internationally recognized standard that sets out criteria for an effective environmental management system. By obtaining this certification, stainless steel manufacturers commit to implementing responsible environmental practices, complying with environmental laws and regulations, and continuously improving their sustainability performance. These certifications require companies to assess their environmental impact, establish goals and targets for improvement, and regularly monitor and report on their progress. By holding environmental certifications, stainless steel manufacturers showcase their dedication to minimizing their environmental footprint, promoting transparency, and contributing to the preservation of natural resources for future generations.

Embracing the Circular Economy Concept:

Adopting a circular economy approach is crucial for the long-term sustainability of stainless steel sheets. This approach revolves around three key principles:

Design for Durability:

In the pursuit of sustainability, engineers and designers have recognized the significance of designing stainless steel sheets that exhibit exceptional durability. By developing materials that can withstand prolonged use and resist mechanical wear, companies can minimize the frequency of replacements and extend the overall lifespan of stainless steel products, a vital aspect of sustainable manufacturing. Through the incorporation of innovative production techniques and advanced material science, engineers aim to enhance the strength, corrosion resistance, and fatigue resistance of stainless steel sheets. By creating durable stainless steel materials, manufacturers can reduce the need for frequent replacements, resulting in significant resource and energy savings over the long term. Not only does designing for durability contribute to sustainable practices, but it also improves product quality and customer satisfaction.

Repair and Refurbishment:

Another strategy for promoting sustainability in the stainless steel industry is to encourage the repair and refurbishment of stainless steel products rather than discarding them when they no longer function optimally. Instead of ending up in landfills and contributing to waste generation, stainless steel products can undergo repairs and refurbishment to extend their usable life. Manufacturers can work closely with repair and maintenance services to develop efficient and cost-effective repair programs that address common issues and prolong the functionality of stainless steel products. By embracing repair and refurbishment practices, companies reduce the demand for new products, conserve resources, and minimize the environmental impact associated with manufacturing new stainless steel items. This approach also aligns with the principles of the circular economy, promoting the concept of “reduce, reuse, and recycle.”

Efficient Recycling:

Establishing efficient recycling infrastructure and practices is essential for the sustainable utilization of stainless steel materials. By optimizing collection systems, implementing advanced sorting technologies, and promoting awareness about the recyclability of stainless steel sheets, the industry can maximize the amount of recycled stainless steel material in circulation. Recycling stainless steel not only conserves valuable resources but also reduces energy consumption and greenhouse gas emissions associated with primary production methods. To enhance recycling efficiency, manufacturers can collaborate with recycling facilities, invest in advanced sorting equipment, and promote comprehensive recycling programs. Additionally, educating consumers and stakeholders about the recyclability of stainless steel and the benefits of recycling can result in increased participation rates and improved waste management practices. By integrating efficient recycling strategies into the industry, stainless steel producers contribute to the circular economy and foster a more sustainable and resource-efficient future.

Promoting Consumer Responsibility:

Consumers play a vital role in driving the recycling and sustainability of stainless steel sheets. Here are some actionable steps consumers can take:

Choosing Recycled Products:

Making conscious decisions to opt for SS products with a higher recycled content is a crucial step towards promoting a demand-driven market for recycled stainless steel. When consumers actively seek and support products made from recycled materials, they send a powerful message to manufacturers that recycling efforts are prioritized and valued. This increased demand incentivizes manufacturers to invest in sustainable practices and technologies that enable them to incorporate more recycled content into their stainless steel products. By choosing products with higher recycled content, consumers play an integral role in driving the circular economy forward and reducing the reliance on virgin resources. This, in turn, contributes to the conservation of valuable natural resources and helps mitigate the environmental impact associated with primary production methods.

Responsible Disposal:

Proper disposal of stainless steel sheets at the end of their life cycle is of utmost importance in promoting sustainability. Instead of sending these sheets to landfills or mixed waste streams, it is essential to route them to designated recycling facilities. This responsible disposal not only ensures that stainless steel resources are diverted from the waste stream but also enables the recovery of valuable materials through recycling processes. By separating stainless steel sheets from other waste and sending them for recycling, we extend the life cycle of these materials and reduce the need for virgin resources. Proper disposal also helps prevent potential environmental hazards, as stainless steel can corrode and release pollutants if not managed correctly. By adhering to responsible disposal practices, individuals and businesses can actively contribute to the preservation of natural resources and the reduction of waste-related environmental pollution.

Spreading Awareness:

To drive widespread change and foster a culture of sustainability, it is crucial to educate others about the environmental benefits of recycling stainless steel sheets. By spreading awareness, we can promote a deeper understanding of the positive impact that responsible consumption and waste management practices can have on the environment. Awareness campaigns can highlight the energy and resource savings achieved through recycling stainless steel, as well as the reduction in greenhouse gas emissions that result from diverting these materials from landfills. Increased knowledge and understanding empower individuals to make informed choices and take active steps towards sustainable living. Spreading awareness can be done through various channels, including public education initiatives, social media campaigns, community workshops, and collaboration with educational institutions. By collectively promoting the benefits of recycling stainless steel, we can inspire widespread action and create a more sustainable future for generations to come.

Conclusion:

Recycling stainless steel sheets holds immense scientific and environmental significance. By embracing sustainable practices, investing in efficient recycling techniques, and adopting a circular economy mindset, we can ensure the long-term sustainability of stainless steel as a valuable and eco-friendly material. It is essential for all stakeholders, from industry players to individual consumers, to prioritize recycling and sustainability, paving the way for a greener and more sustainable future. Together, we can contribute to a circular economy that thrives on resource conservation, energy efficiency, and waste reduction, ultimately benefiting both present and future generations.