Classification of Stainless Steel Sheet Grades

Definition and Standards of Stainless Steel Sheet Grades

The grades of stainless steel sheets are determined based on international and national standards to differentiate stainless steel sheets of different materials and properties. According to the Chinese National Standard GB/T 1220-2019, the “Stainless Steel Bars” standard provides a naming system for stainless steel sheet grades, offering clear definitions and standards for the classification of stainless steel sheets. National standards typically use numerical representations for stainless steel grades, with each number signifying different characteristics. For example, the first digit in the grade represents the primary material of the stainless steel, the second digit represents the series of stainless steel, and subsequent digits indicate specific material compositions and performance parameters.

Common Stainless Steel Sheet Grades and Their Characteristics

In the steel industry, there are many common stainless steel sheet grades, each with its unique characteristics and applications. Here are some examples of common stainless steel sheet grades:

304 Stainless Steel Sheet

Characteristics: 304 stainless steel sheet is one of the most common types of stainless steel, known for its excellent corrosion resistance and workability. It is commonly used in food processing equipment and decorative materials.

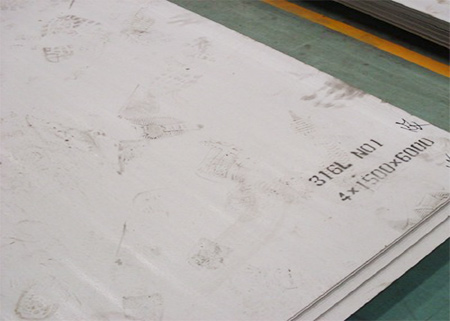

316 Stainless Steel Sheet

Characteristics: 316 stainless steel sheet has even higher corrosion resistance, making it particularly suitable for marine environments and chemical processing equipment.

430 Stainless Steel Sheet

Characteristics: 430 stainless steel sheet is relatively lower in price and is typically used for general-purpose stainless steel products.

Factors Affecting the Price of Stainless Steel Sheets

Raw Material Costs

The price of stainless steel sheets is influenced by raw material costs, including the primary components of stainless steel such as iron, nickel, chromium, titanium, and more. Fluctuations in the prices of these raw materials in the international market directly impact the price of stainless steel sheets.

Production Processes and Equipment

The use of different production processes and equipment can affect the cost and price of stainless steel sheets. Advanced production processes and equipment can improve production efficiency, thereby reducing the production costs of stainless steel sheets.

Market Supply and Demand

Market supply and demand dynamics play a crucial role in determining the price of stainless steel sheets. Fluctuations in demand and supply in the market can lead to price fluctuations. For instance, high demand may drive prices up, while low demand may lead to price decreases.

Brand and Quality Factors

Stainless steel sheets from different brands may have varying prices, influenced by brand reputation and product quality. High-quality stainless steel sheets often command higher prices due to their superior performance and durability.

Price Differences Among Different Grades of Stainless Steel Sheets

Price Range of Stainless Steel Sheets

Different grades of stainless steel sheets have price ranges. Typically, more common grades have lower prices, while more specialized or high-performance grades have higher prices.

Price Comparison of Different Grades of Stainless Steel Sheets

We can understand the differences between stainless steel sheet grades by comparing their prices. Here are some price comparison examples:

Grade Price Range 304 Stainless Steel Sheet $2142 – $3285 316L Stainless Steel Sheet $3928 – $5428 430 Stainless Steel Sheet $1171 – $1714

Trend Analysis of Stainless Steel Sheet Prices

Stainless steel sheet prices are influenced by various factors, leading to price fluctuations over time. Trend analysis allows us to understand the changing trends in stainless steel sheet prices, aiding in making informed purchasing decisions.

How to Choose the Right Stainless Steel Sheet Grade

Selection Based on Usage Environment and Requirements

When choosing the appropriate stainless steel sheet grade, the usage environment and requirements should be considered first. For instance, environments with high corrosion need grades with excellent corrosion resistance, such as 316 stainless steel sheets. If mechanical properties are the primary concern, high-strength grades suitable for the application can be selected.

Balancing Price and Performance Factors

When selecting a stainless steel sheet grade, it’s essential to consider not only performance factors but also price factors. The highest-priced grade may not always be the best choice. Balancing performance and price according to your budget and performance requirements is necessary to meet the specific needs of your application.

Seek Advice from Professionals

If you are unsure about choosing the right stainless steel sheet grade, it is advisable to seek advice from professionals. Engineers or materials experts can provide useful advice and guidance tailored to your specific application, helping you make informed decisions.