Introduction

In the steel industry, stainless steel coils, as an important material, are widely used in HVAC (Heating, Ventilation, and Air Conditioning) systems. Choosing the appropriate thickness for stainless steel coils is crucial for system performance and reliability. This article will focus on how to assess the requirements of HVAC systems to determine the suitable thickness for stainless steel coils.

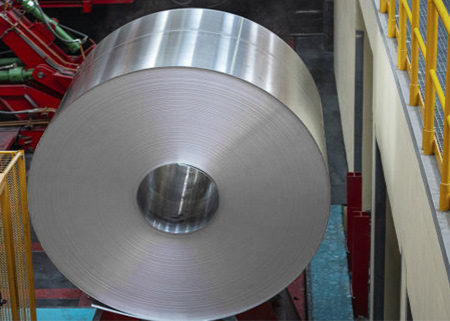

Basic Overview of Stainless Steel Coils

Applications of Stainless Steel Coils

Stainless steel coils have a wide range of applications in the steel industry, including key components in HVAC systems such as pipes, heat exchangers, and condensers. Their corrosion resistance and thermal performance make them an ideal material choice.

Importance of Stainless Steel Coils

The importance of stainless steel coils in HVAC systems cannot be underestimated. They can resist the corrosive effects of humidity, oxygen, and chemicals, ensuring the long-term stability of the system. Additionally, stainless steel coils have excellent thermal properties, facilitating efficient heat and cold transfer, thereby improving system energy efficiency and performance stability.

Evaluating Requirements for HVAC Systems

Temperature and Environmental Conditions

Before selecting the thickness of stainless steel coils, it’s essential to evaluate the temperature and environmental conditions of the HVAC system. Different temperature and environmental conditions impose varying requirements on the corrosion resistance and thermal performance of stainless steel coils. For example, in high-temperature environments, stainless steel coils with high heat resistance must be chosen.

Mechanical Performance Requirements

Components in HVAC systems often need to withstand certain mechanical stresses. Therefore, evaluating mechanical performance requirements is crucial when selecting the thickness of stainless steel coils. Depending on the specific stress conditions, choosing an appropriate thickness ensures the system’s strength and stability.

Corrosion Resistance Requirements

HVAC systems often face challenges from humidity and chemical substances, making corrosion resistance a critical consideration when choosing the thickness of stainless steel coils. Depending on the specific corrosion resistance requirements, selecting stainless steel coils with higher corrosion resistance is necessary to ensure the long-term stability of the system.

Selecting the Right Thickness for Stainless Steel Coils

Impact of Thickness on Mechanical Performance

The thickness of stainless steel coils directly affects their mechanical performance. In general, thicker stainless steel coils have higher strength and stiffness, enabling them to withstand greater mechanical stresses. Therefore, choosing thicker stainless steel coils is appropriate for applications that require higher strength and stiffness.

Relationship Between Thickness and Corrosion Resistance

The corrosion resistance of stainless steel coils is closely related to their thickness. Thicker stainless steel coils can provide better corrosion resistance, effectively resisting the effects of humidity, oxygen, and chemical substances. Therefore, choosing thicker stainless steel coils is necessary in environments where high corrosion resistance is required.

Considerations for Low-Temperature Environments

In low-temperature environments, the selection of stainless steel coil thickness needs to consider its resistance to cold brittleness. Thicker stainless steel coils can provide better resistance to cold brittleness, maintaining their mechanical and corrosion resistance properties at low temperatures. Therefore, choosing thicker stainless steel coils is essential in low-temperature environments.

Considerations for High-Temperature Environments

In high-temperature environments, the selection of stainless steel coil thickness should consider its heat resistance. Thicker stainless steel coils can offer better heat resistance, maintaining their mechanical and corrosion resistance properties at high temperatures. Therefore, choosing thicker stainless steel coils is necessary in high-temperature environments.

Relationship Between Production Processes and Thickness

The production processes of stainless steel coils are closely related to their thickness. Different production processes may have certain limitations on the thickness of stainless steel coils. Therefore, when selecting the thickness of stainless steel coils, it’s necessary to consider the feasibility and applicability of production processes.

Impact of Thickness on Costs

The thickness of stainless steel coils also has an impact on costs. Generally, thicker stainless steel coils tend to be relatively more expensive. Therefore, when choosing the thickness of stainless steel coils, it’s important to consider performance requirements and cost factors together to find a balance.

Conclusion

In the steel industry, choosing the right thickness for stainless steel coils requires considering the relationship between thickness and performance, determining thickness based on environmental conditions, and taking into account quality control and cost considerations. Depending on specific application requirements, selecting the appropriate thickness for stainless steel coils ensures product performance and reliability. Additionally, attention should be paid to the composition and material properties of stainless steel coils, as well as the feasibility and applicability of production processes. By comprehensively considering performance requirements and cost factors, finding the right thickness for stainless steel coils will lead to improved outcomes in the steel industry.