The manufacturing process of stainless steel sheets involves several key steps, each crucial to the quality and performance of the final product. Here is a detailed overview of the process:

Smelting Raw Materials

Raw Material Selection:

- The primary raw materials for stainless steel include iron ore, chromium ore, nickel ore, and other alloying elements. These materials are carefully selected to ensure the final product’s composition meets the required standards.

Smelting Process:

- Electric Arc Furnace Smelting: The raw materials are placed into an electric arc furnace, where they are melted by an electric arc. At high temperatures, the iron and alloying elements mix to form a liquid stainless steel alloy. The electric arc furnace allows precise control over the smelting temperature and alloy composition.

- Converter Smelting: In some cases, converter smelting is used. This process typically involves processing scrap steel, where oxygen is blown into the furnace to remove impurities and adjust the composition.

Alloying:

- During smelting, elements such as chromium, nickel, and molybdenum are added as needed to adjust the chemical composition and properties of the stainless steel. The accuracy of alloying directly affects the corrosion resistance, strength, and other properties of the stainless steel sheets.

Hot Rolling

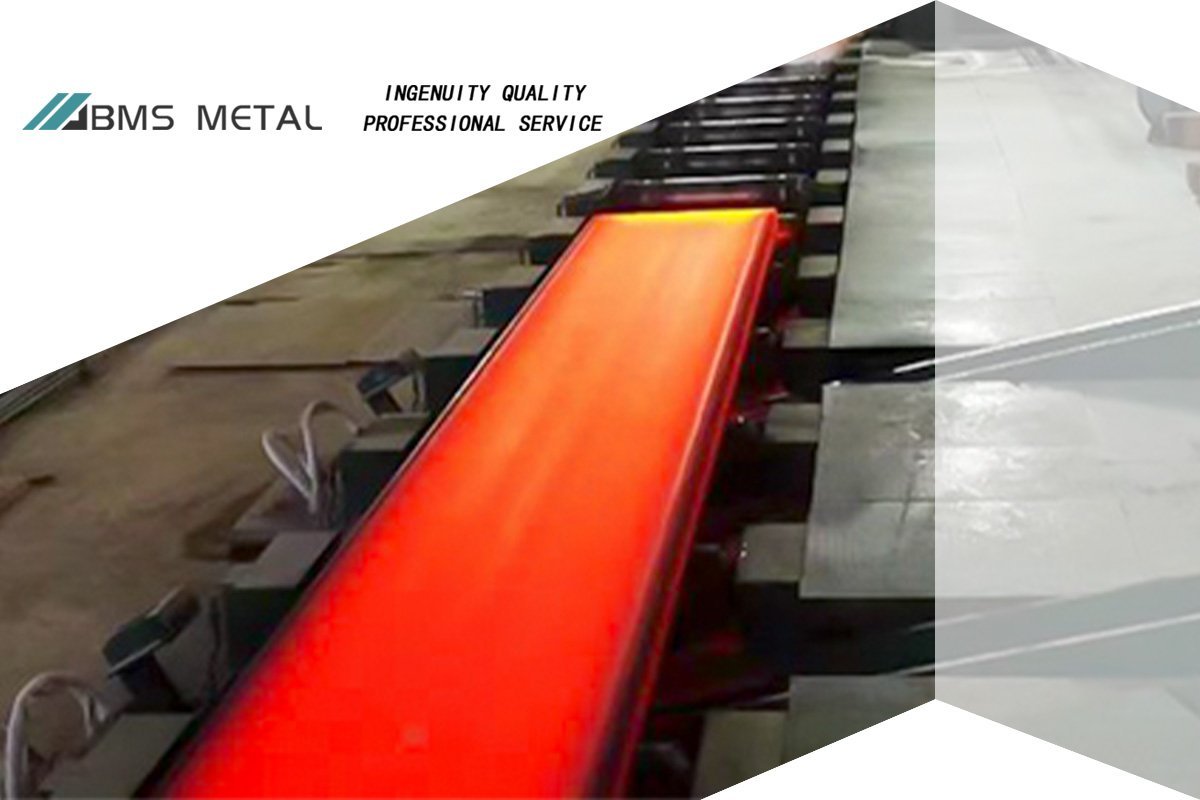

Initial Forming:

- Hot Rolling Process: The molten stainless steel alloy is cast into slabs, which are then rolled into thicker sheets through a series of hot rolling mills. During hot rolling, the stainless steel becomes softer at high temperatures, making it easier to shape into the desired thickness and dimensions.

Thickness and Width Control:

- During hot rolling, the thickness and width of the sheets are precisely controlled by adjusting the roll gap and temperature. Hot-rolled stainless steel sheets are typically used to manufacture thicker sheets and large-sized coils.

Cold Rolling

Further Processing:

- Cold Rolling Process: The hot-rolled sheets are further rolled at room temperature to improve surface quality and dimensional accuracy. Cold rolling can achieve the required thinness, smoothness, and precision for stainless steel sheets.

Surface Treatment:

- During cold rolling, surface treatments such as brushing or mirror polishing can be applied to enhance appearance and performance. Cold-rolled stainless steel sheets are suitable for applications requiring high surface quality and precision.

Annealing

Stress Relief and Performance Improvement:

- Annealing Process: The cold-rolled stainless steel sheets are heated to a specific temperature and then slowly cooled to remove internal stresses generated during processing. This process also improves the plasticity and toughness of the stainless steel sheets.

Performance Adjustment:

- The temperature and cooling rate during annealing significantly affect the final properties of the stainless steel sheets. Annealing can optimize the mechanical properties and corrosion resistance of the sheets.

Pickling

Removing Surface Oxides:

- Pickling Process: An acidic solution (such as sulfuric or hydrofluoric acid) is used to treat the surface of the stainless steel sheets, removing oxides, dirt, and impurities. This step improves surface smoothness and prepares the sheets for subsequent processing.

Surface Quality Improvement:

- After pickling, the surface of the stainless steel sheets becomes smoother, facilitating further processing and decorative treatments. The treated surface also has enhanced corrosion resistance.

Final Inspection and Cutting

Quality Inspection:

- After completing all processing steps, the stainless steel sheets undergo a final quality inspection, including checks for dimensions, surface quality, chemical composition, and mechanical properties.

Cutting and Packaging:

- Based on customer requirements, the inspected stainless steel sheets are cut into the desired sizes and shapes. Finally, the sheets are packaged and prepared for shipment to the customers.

These detailed process steps ensure that stainless steel sheets meet the required quality standards and performance requirements. Each step requires precise control and supervision to ensure the stability and reliability of the final product.