Introduction

Stainless steel plates are flat, rectangular metal sheets widely used in construction, manufacturing, and industrial applications due to their durability, corrosion resistance, and versatility. This guide covers everything buyers need to know—from composition and grades to selection tips and global standards.

What is Stainless Steel Plate?

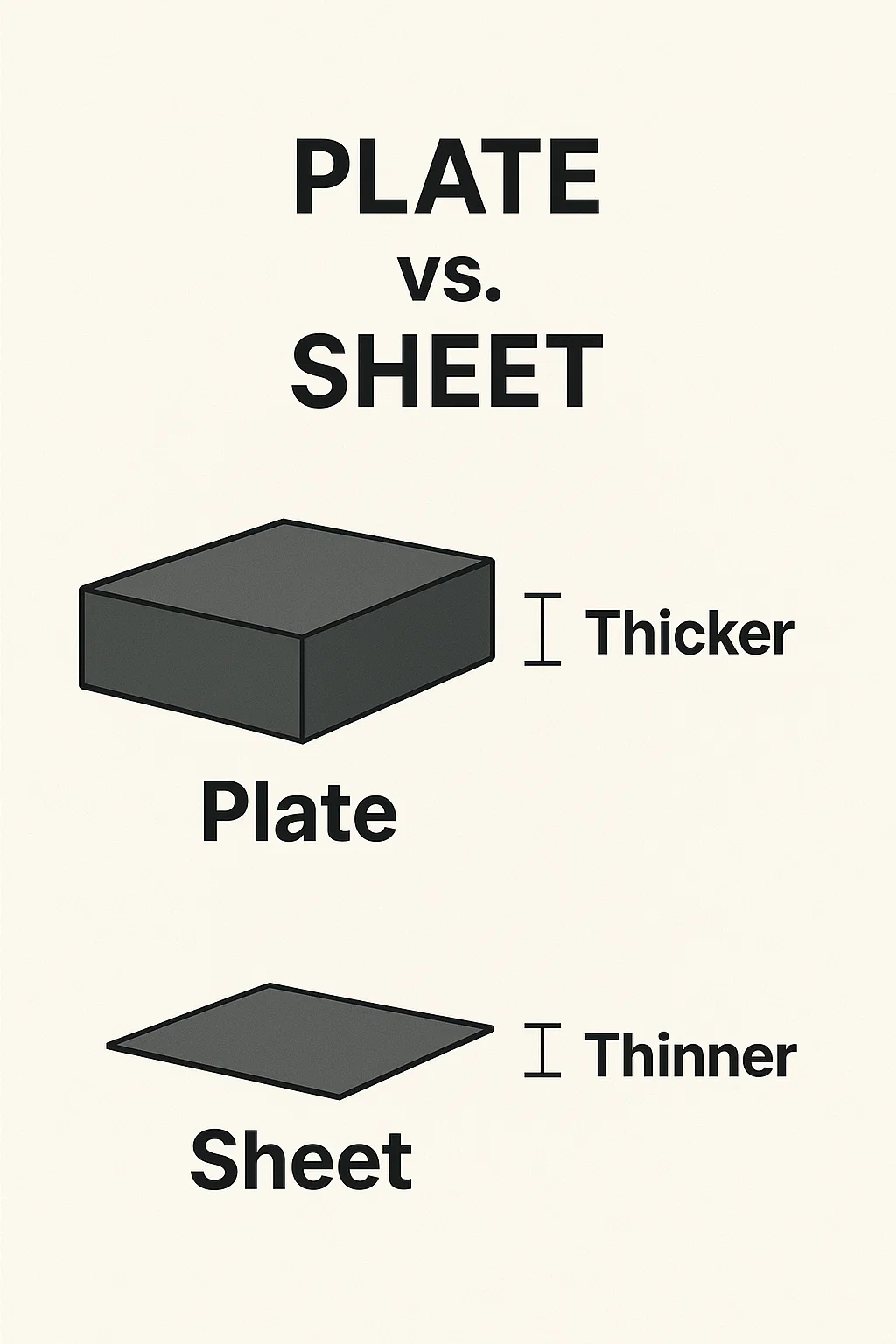

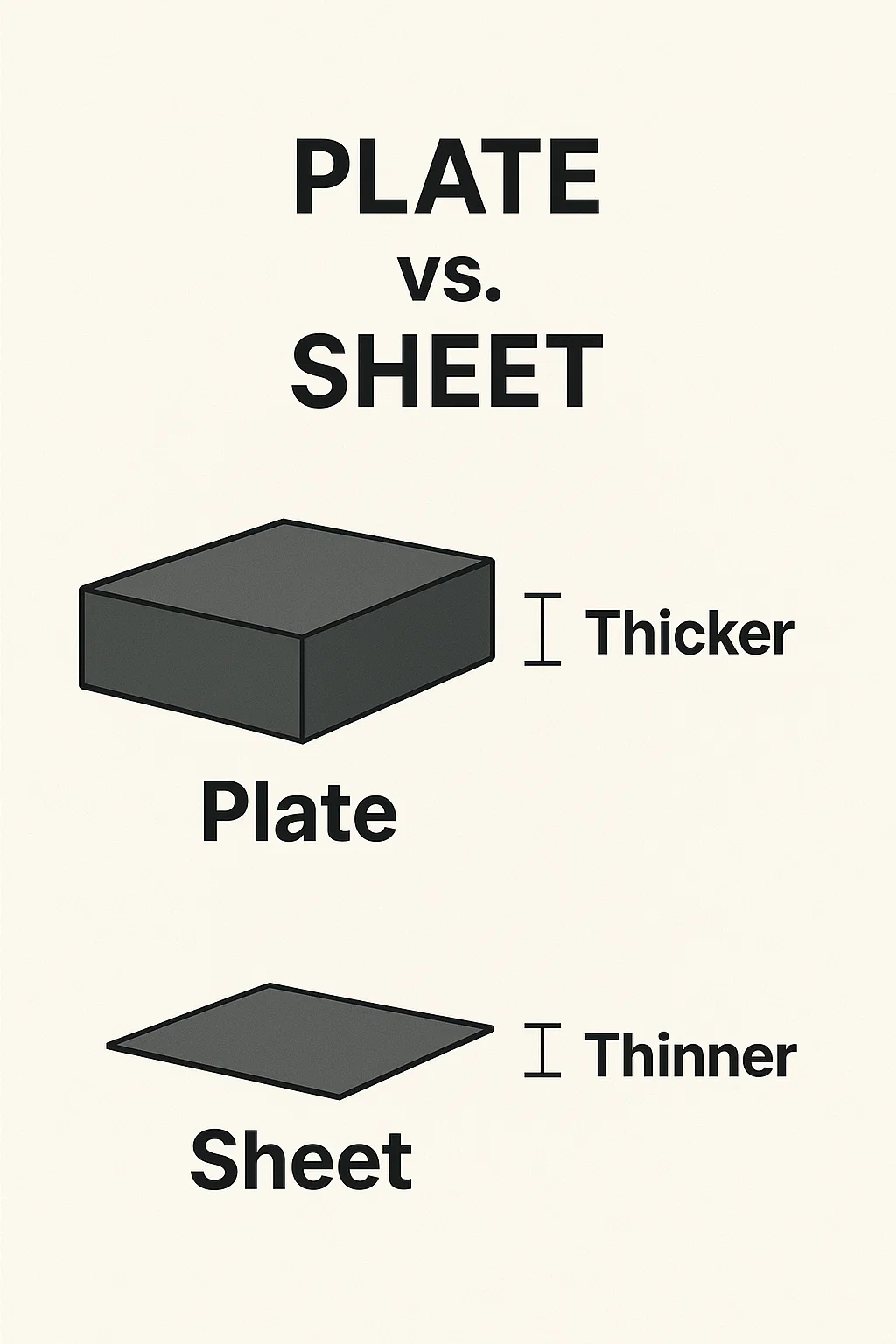

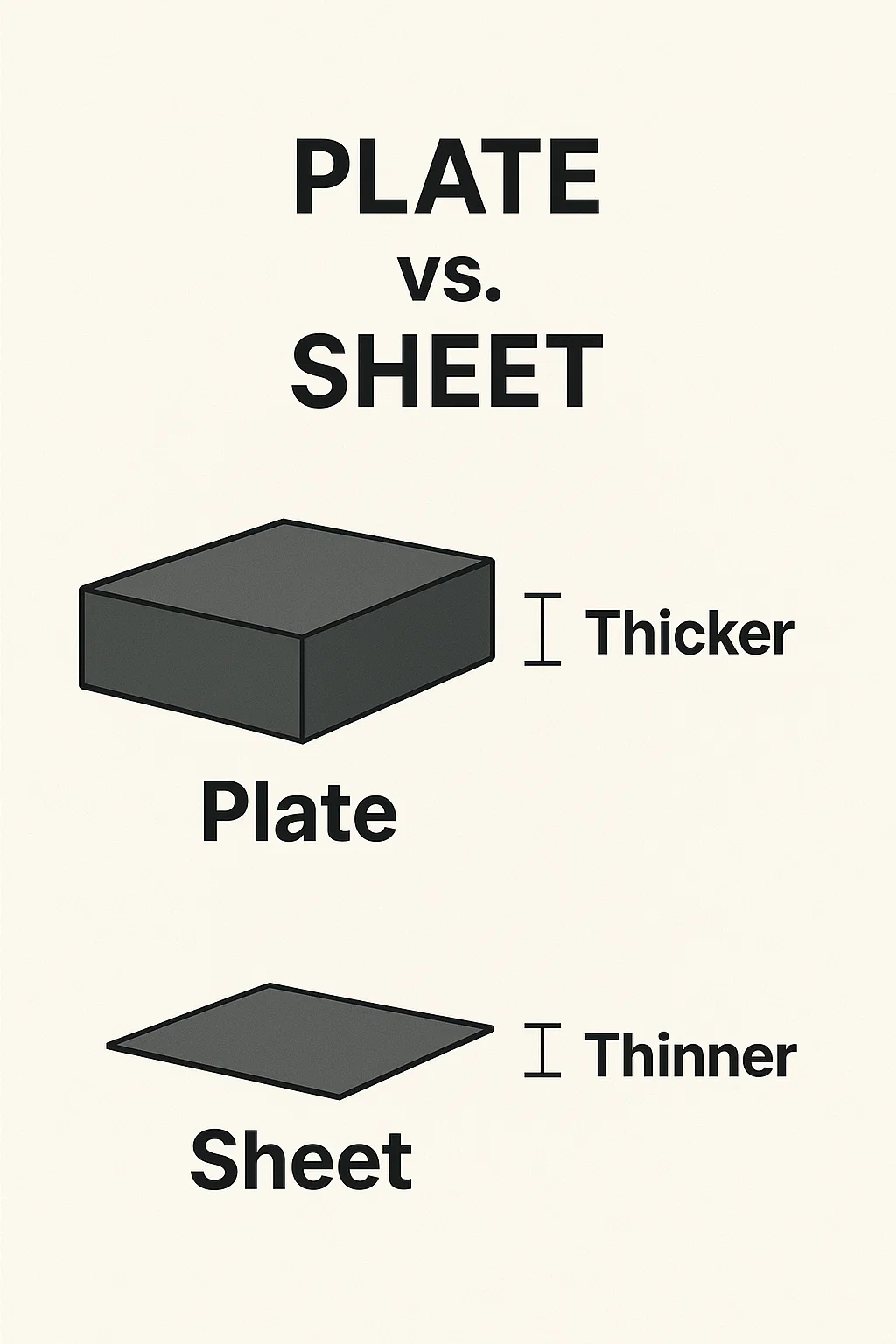

Stainless steel plates (or SS plates) are flat-rolled metal sheets with a minimum thickness of 0.05mm (thinner sheets are called “stainless steel sheets”). The primary way to differentiate between stainless steel plates and sheets is their thickness. Generally, any piece of stainless steel that exceeds 6mm (approximately 0.236 inches) in thickness is classified as a plate. In the United States, this distinction is often made at a slightly thinner gauge, around 0.188 inches (which corresponds to 7 gauge), with anything thinner being considered a sheet.

Key distinction: Plates are thicker (>5mm) and stronger than sheets, suited for heavy-duty use.

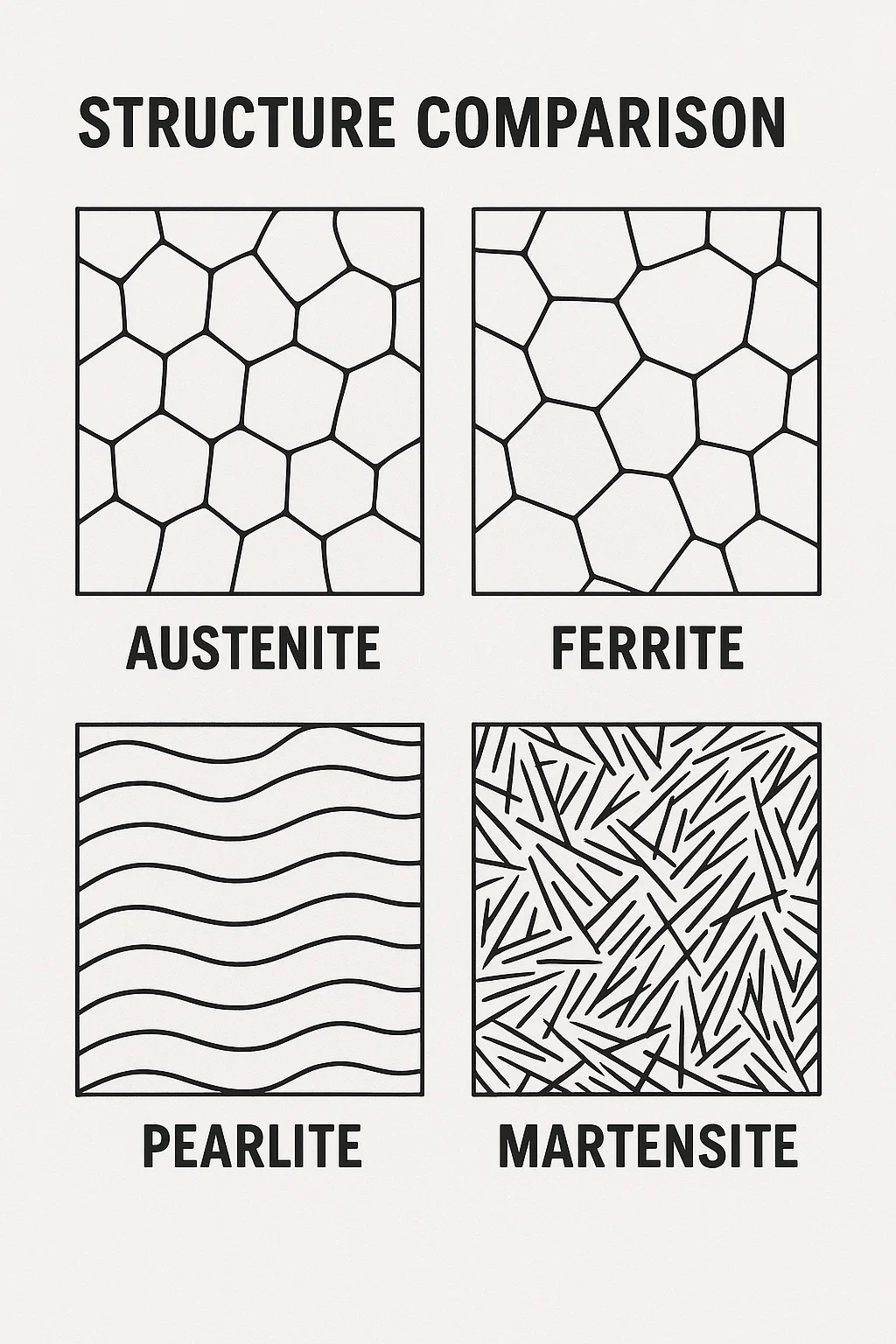

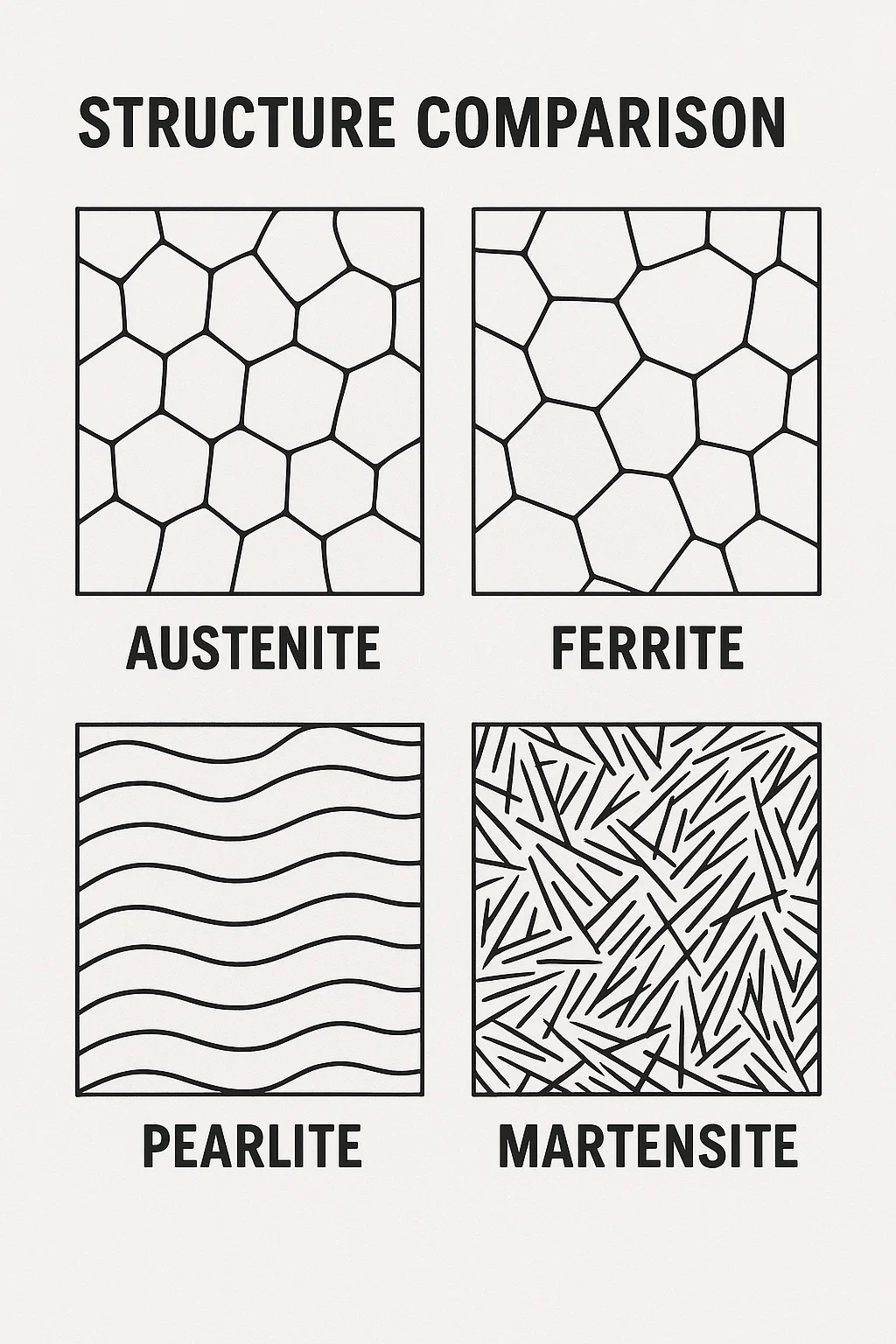

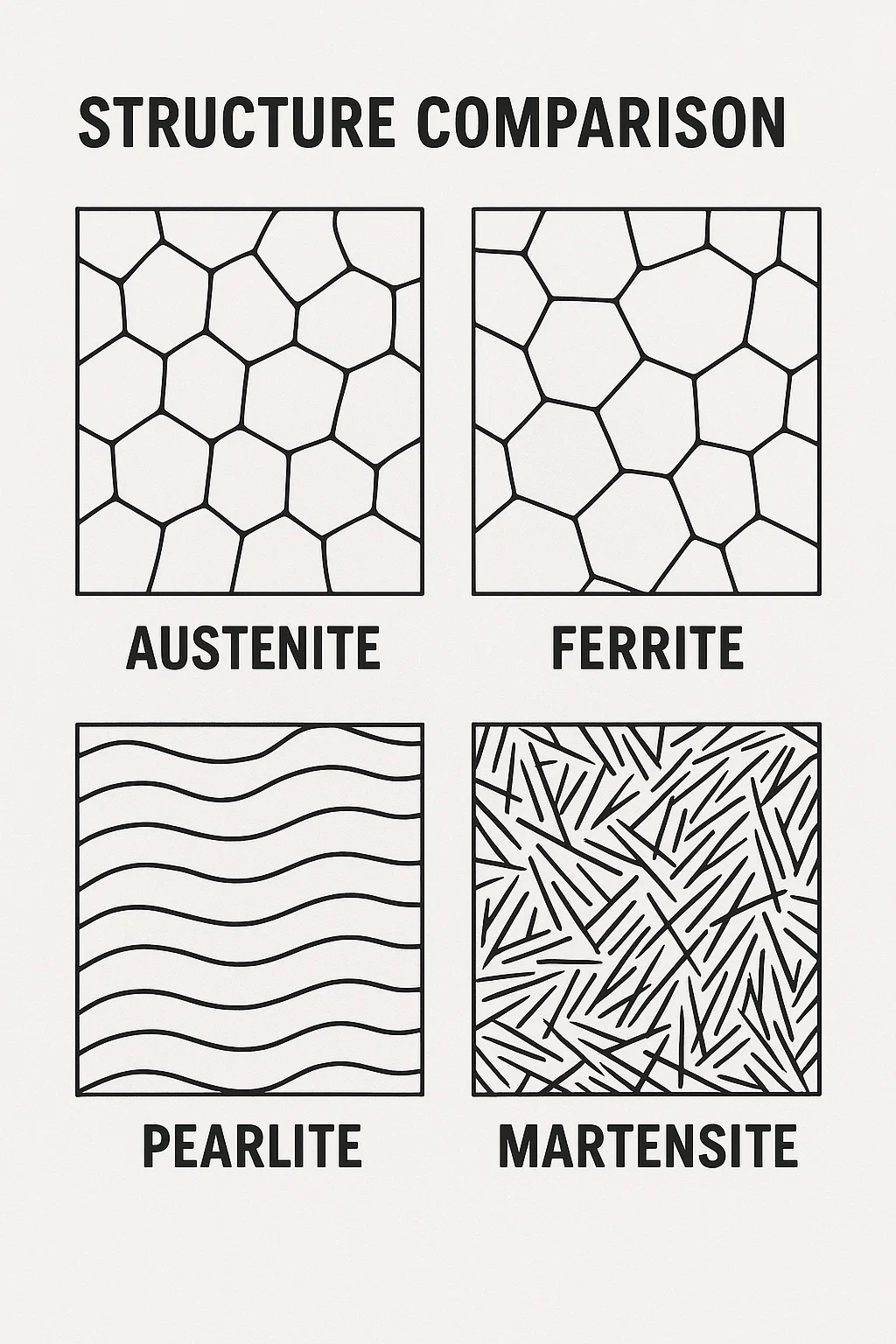

The Four Key Microstructural Categories

- Austenitic stainless steel plates

- Martensitic stainless steel plates (including precipitation-hardening grades)

- Ferritic stainless steel plates

- Austenitic-ferritic duplex stainless steel plates

Key Characteristics of Stainless Steel Plates

Corrosion Resistance

- Comparable to nickel-chromium alloy 304 in resisting general corrosion.

- Prolonged heating within carbide precipitation temperature ranges may reduce resistance in alloys 321/347 for harsh environments.

- Ideal for high-temperature applications requiring strong anti-sensitization to prevent intergranular corrosion.

High-Temperature Oxidation Resistance

- Excellent oxidation resistance at elevated temperatures.

- Oxidation rates depend on:

Exposure environment (oxygen levels, contaminants).

Product form (thickness, surface finish).

Thermal Conductivity & Surface Efficiency

- Total heat transfer depends on:

Thermal conductivity of the metal.

Surface conditions (cleanliness reduces thermal resistance vs. rust-prone metals).

- Stainless maintains cleaner surfaces, enabling better heat transfer than some higher-conductivity metals.

Mechanical & Processing Properties

- Superior bendability, weldability, and post-weld toughness.

- High strength (≥730MPa) with ≥12% martensite volume fraction after heat treatment (850–1250°C, cooled at ≥1°C/s).

- Optimized composition (C≤0.02%, Cr 11–17%, Mo/B additives) enhances:

Punching performance in welded sections.

Intergranular corrosion resistance.

Aesthetic & Decorative Benefits

- Rich visual appeal: Offers diverse finishes (brushed, mirrored, colored) with strong 3D effects.

- Design versatility: Complements modern, industrial, minimalist, and luxury styles.

Safety & Sustainability

- Fireproof & moisture-resistant: Withstands -196°C to 800°C extremes.

- Eco-friendly: Zero formaldehyde/radiation emissions; 100% recyclable.

- Low maintenance: Easy to clean (avoid strong alkaline solutions).

Limitations

- Higher cost vs. alternatives (acrylic, aluminum, plastic).

- Flame-cutting challenges: Requires plasma/laser cutting due to oxidation resistance.

Common Surface Finishes and Their Applications

- 2B: Matte finish, ideal for industrial and kitchen use.

- BA (Bright Annealed): Smooth, reflective surface for appliances.

- No.4 (Brushed): Good for architectural cladding and elevators.

- No.8 (Mirror): High-end decor, signage.

- Hairline (HL): Modern design, interior walls, panels.

Surface Manufacturing Processes

Process | Description | Key Advantages |

Electroplating | Electrolytic metal deposition | Corrosion prevention, wear resistance |

Electroless Plating | Chemical coating process | Uniform thickness, no electricity needed |

Fluorocarbon Coating | PVDF-based resin coating | Weather resistance, self-cleaning |

Spray Painting | Compressed air atomized paint | Custom colors, decorative appeal |

Applications of Stainless Steel Plate

- Construction: Bridges, facades, reinforcement.

- Industrial: Chemical tanks, pressure vessels.

- Transportation: Shipbuilding, aircraft components.

- Consumer Goods: Kitchen equipment, surgical tools.

Standard Sizes and Thickness Range

Stainless steel plates are typically available in standard sizes such as 4ft x 8ft and 5ft x 10ft, but custom dimensions are also widely supported. Thickness generally ranges from 5mm to over 100mm. For precision applications, always check if the product meets dimensional tolerances based on international standards such as ASTM, SUS, GB or EN.

Packaging and Shipping Requirements

Due to their weight and surface sensitivity, stainless steel plates should be packed in padded wooden crates or securely metal-strapped bundles to prevent damage. Reliable suppliers provide various shipping options including sea freight, air cargo, and container consolidation. Standard export documents—such as packing list, mill test certificate (MTC), and certificate of origin—should always be included.

What Affects Stainless Steel Plate Pricing?

Pricing depends on several key factors including material grade (e.g., 304, 316), thickness, finish type, and order quantity. Some suppliers quote pricing per kilogram or ton, while others use per piece—buyers should confirm the pricing method in advance. Also, clarify the Minimum Order Quantity (MOQ) requirement before placing an order.

Lead Time and Stock Availability

Popular sizes and finishes are usually in stock and ready for immediate shipment. However, custom thicknesses, surface treatments, or cut-to-size options may require a lead time of 5–20 business days. Urgent orders can sometimes be fast-tracked for an additional fee—availability varies by supplier.

Machining and Processing Compatibility

Before purchase, confirm whether the plates are suitable for laser, plasma, or water jet cutting. Most stainless steel plates are readily weldable, drillable, and bendable, especially austenitic grades. Ensure that the plate is compatible with your existing equipment and filler materials to avoid performance issues during fabrication.

Regulatory Compliance and Certifications

- FDA compliance is necessary for food-contact applications.

- RoHS and REACHcertifications are important in electronics and consumer goods.

- Marine-grade certificationssuch as ABS, DNV, or Lloyd’s Register are required for shipbuilding.

Industries like aerospace, oil & gas, pharmaceuticals, and nuclear often require full material traceability.

Conclusion

Purchasing stainless steel plates is more than just selecting a metal slab. From grades and finishes to processing properties and compliance, the ideal plate depends heavily on your application needs. If you have any questions or need assistance with selecting the right stainless steel plate, our team is here to help—feel free to reach out anytime.

FAQ

Can SS plates be welded?

Yes, but use low-carbon grades (304L) or post-weld annealing to prevent corrosion.

What is the difference between stainless steel and aluminum?

Stainless steel has higher strength and superior corrosion resistance compared to aluminum. However, it is also heavier and more expensive. Aluminum is better suited for applications where weight reduction is critical, while stainless steel is ideal for structural integrity and harsh environments.

How to calculate SS plate weight?

Formula: Weight (kg) = Thickness (mm) × Width (m) × Length (m) × Density (8.0 g/cm³)

Example:

A stainless steel plate that is 10mm thick, 1.5 meters wide, and 2 meters long:

Weight = 10 × 1.5 × 2 × 8.0 = 240 kg

This formula gives you a close estimate, though the actual weight can slightly vary based on the specific grade and finish.

Is galvanized steel a good alternative to stainless steel?

Galvanized steel is often cheaper than stainless steel and provides basic corrosion protection due to its zinc coating. However, it is less durable in corrosive or high-temperature environments. Over time, the zinc layer can wear off, exposing the steel underneath. For long-term reliability, stainless steel is the better choice.