- Title: Stainless Steel Strip Coil: Comprehensive Guide for Precision Manufacturing

- Meta Description: Discover the importance, types, and applications of stainless steel strip coil. Learn about the manufacturing process, quality considerations, and how to choose the right coil for your industry.

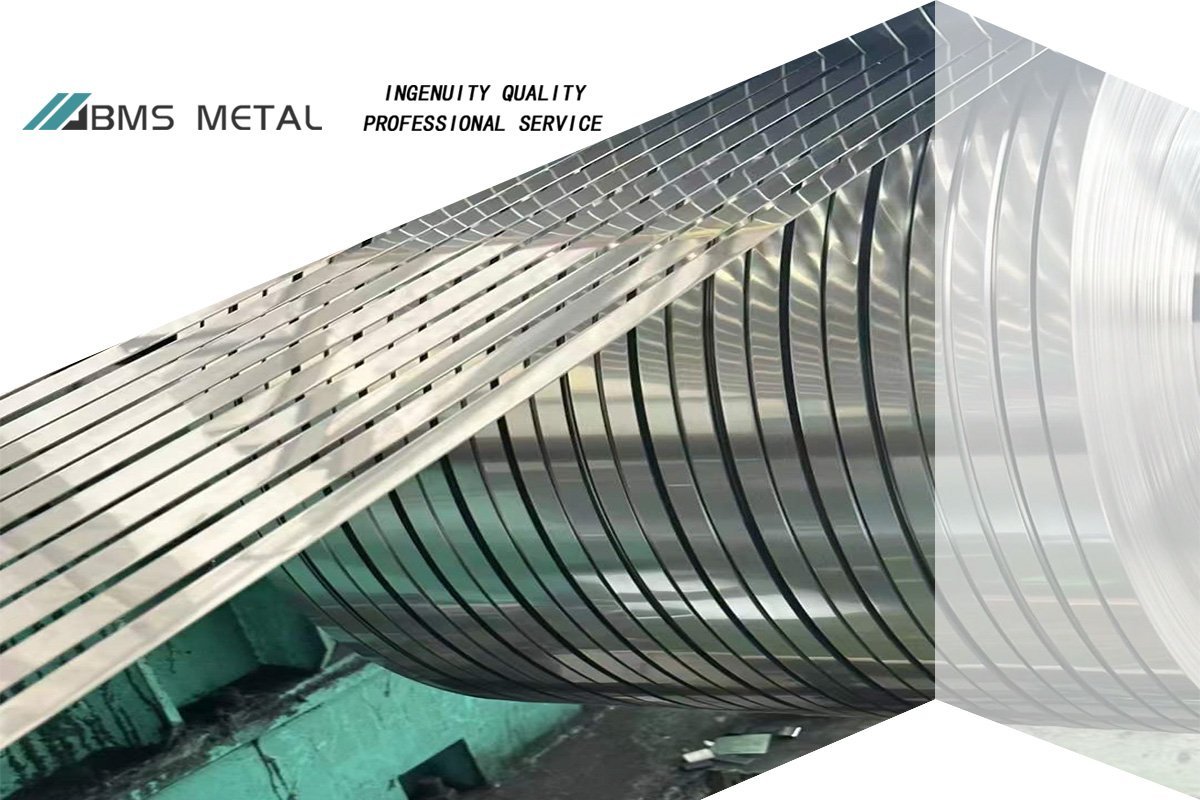

H2: What is Stainless Steel Strip Coil?

Introduction:

Stainless steel strip coil is a thin, flat-rolled metal product that is coiled after being processed. Known for its versatility, stainless steel strip coil is widely used across various industries, including automotive, aerospace, electronics, and medical devices. Its importance lies in its ability to be easily fabricated into various components while maintaining excellent corrosion resistance and durability, making it a vital material in precision manufacturing.

Key Characteristics:

Stainless steel strip coil is distinguished by several core properties:

- Corrosion Resistance: Stainless steel’s inherent resistance to rust and oxidation ensures longevity, even in harsh environments.

- Durability: It offers high tensile strength and impact resistance, making it suitable for demanding applications.

- Precision: Stainless steel strip coils are manufactured to tight tolerances, allowing for consistent performance and dimensional accuracy in critical components.

These characteristics make stainless steel strip coil an indispensable material in applications that require reliability, strength, and longevity.

Why is Stainless Steel Strip Coil Important in Manufacturing?

What are the Common Applications of Stainless Steel Strip Coil?

Stainless steel strip coil plays a crucial role in several key industries due to its versatility and reliability:

- Automotive: Used in exhaust systems, fuel lines, and structural components due to its strength and corrosion resistance.

- Aerospace: Essential for precision parts like engine components and fasteners, where high performance under stress is required.

- Electronics: Utilized in connectors, springs, and shields thanks to its conductivity and formability.

- Medical Devices: Chosen for surgical instruments and implants because of its biocompatibility and durability.

How Does Stainless Steel Strip Coil Enhance Product Quality?

Stainless steel strip coil enhances product quality in manufacturing through several key properties:

- Surface Finish: The smooth, consistent surface of stainless steel strip coil ensures an aesthetically pleasing finish and reduces friction in moving parts.

- Mechanical Strength: Its high tensile strength supports structural integrity in products, leading to longer-lasting and more reliable components.

- Dimensional Accuracy: Manufactured to tight tolerances, stainless steel strip coils provide precise dimensions, crucial for high-performance applications where exact measurements are essential.

These attributes contribute to the overall performance and longevity of products, making stainless steel strip coil a preferred material in quality-driven manufacturing processes.

What Are the Types of Stainless Steel Strip Coil?

What are the Differences Between Austenitic, Ferritic, and Martensitic Stainless Steel Coils?

Stainless steel strip coils come in three primary types, each with distinct properties and applications:

Austenitic Stainless Steel: This type, including grades like 304 and 316, is known for its excellent corrosion resistance and formability. It’s non-magnetic and often used in applications requiring high durability, such as kitchen equipment and chemical containers.

Ferritic Stainless Steel: Typically containing lower carbon levels, ferritic stainless steels like 430 offer good corrosion resistance and are magnetic. They are often used in automotive trim, appliances, and industrial equipment.

Martensitic Stainless Steel: Characterized by its high strength and hardness, martensitic stainless steel, such as grade 410, is used where wear resistance is critical, like in cutlery and turbine blades. However, it has lower corrosion resistance compared to austenitic and ferritic types.

How to Choose the Right Stainless Steel Strip Coil?

Selecting the right stainless steel strip coil depends on the specific requirements of your application:

- Corrosion Resistance: For environments exposed to moisture or chemicals, austenitic stainless steels like 304 or 316 are ideal due to their superior corrosion resistance.

- Strength and Hardness: If your application demands high strength and resistance to wear, martensitic stainless steel is the best choice, though it may require additional corrosion protection.

- Formability and Magnetism: Ferritic stainless steel is suitable for applications needing moderate corrosion resistance, ease of fabrication, and magnetic properties, making it a good choice for automotive or structural uses.

Carefully considering these factors ensures the selection of a stainless steel strip coil that will perform effectively in your specific application.

How is Stainless Steel Strip Coil Manufactured?

What Are the Key Steps in the Production Process?

The manufacturing of stainless steel strip coil involves several crucial steps:

- Cold Rolling: The stainless steel is passed through rollers at room temperature to achieve the desired thickness, enhancing its strength and surface finish.

- Annealing: The strip is heat-treated to remove internal stresses and improve its ductility, making it easier to form and shape.

- Slitting: The wide strip is cut into narrower coils according to the required width, ensuring precision for various applications.

What Are the Benefits of Precision Rolling?

Precision rolling offers significant advantages, including:

- Tight Tolerances: Achieving precise thickness and width ensures consistency in performance, especially in high-precision industries like electronics and medical devices.

- Superior Surface Finish: The smooth surface obtained through precision rolling enhances the aesthetic appeal and reduces friction in mechanical components, contributing to the overall quality of the final product.

What Should You Consider When Purchasing Stainless Steel Strip Coil?

How to Assess Quality and Certification?

When purchasing stainless steel strip coil, it’s essential to evaluate quality through certifications:

- ASTM and ISO Standards: Ensure that the material meets recognized standards such as ASTM and ISO, which guarantee its quality, performance, and suitability for your application.

- Material Test Reports (MTRs): Request MTRs from your supplier to verify the material’s chemical composition and mechanical properties, ensuring it meets your specific requirements.

What Role Does Supplier Reliability Play?

Selecting a reliable supplier is crucial for:

- Consistent Quality: A trustworthy supplier will provide stainless steel strip coils that consistently meet the required specifications, ensuring uniformity across batches.

- Timely Delivery: Reliable suppliers have efficient logistics, ensuring that your orders are delivered on time, avoiding delays in production.

- Technical Support: Access to expert advice and support from your supplier can be invaluable, particularly when selecting the right material for complex applications.

Conclusion: Why Stainless Steel Strip Coil is Essential for Your Industry

Summary:

Stainless steel strip coil is a vital material in numerous industries due to its exceptional corrosion resistance, durability, and precision. From automotive to medical devices, its versatility and quality enhance product performance and longevity. Understanding the manufacturing process, assessing quality, and choosing the right supplier are key to maximizing the benefits of stainless steel strip coil in your applications.

FAQ:

Are stainless steel coils better?

Stainless steel coils are considered superior in many applications due to their excellent corrosion resistance, durability, and strength. They are especially valuable in environments where exposure to moisture, chemicals, or high temperatures is common. The choice of stainless steel coil often depends on the specific requirements of the application, including the need for longevity and maintenance of structural integrity.

What is the difference between steel coil and steel strip?

The primary difference between steel coil and steel strip lies in their width and thickness. A steel coil is typically a rolled form of steel, which can be cut into specific lengths or widths. Steel strip, on the other hand, is narrower and thinner, often cut from a larger coil. Steel strips are used in applications requiring precise dimensions, while coils are more versatile and can be processed into various forms.

Does stainless steel work on coil?

Yes, stainless steel is commonly processed into coils, which are then used in various manufacturing processes. The coiled form allows for easy storage, transportation, and further processing such as slitting, cutting, or forming into specific shapes. Stainless steel coils maintain their properties, such as corrosion resistance and strength, throughout these processes, making them ideal for a wide range of applications.