Introduction:

Corrosion is a natural process that can cause damage to metal materials in various environments. However, certain materials exhibit an exceptional resistance to corrosion, making them highly suitable for applications where durability and longevity are crucial. Stainless steel sheets are among these materials, renowned for their remarkable corrosion resistance properties. In this article, we will explore the factors that contribute to the corrosion resistance of stainless steel sheets and their wide range of applications.

Composition of Stainless Steel:

Stainless steel sheets/plates are primarily composed of iron, chromium, and various alloying elements like nickel, molybdenum, and titanium. The presence of chromium plays a vital role in imparting corrosion resistance to the material. The chromium content in stainless steel typically ranges from 10% to 30%. It forms a thin, passive layer of chromium oxide on the surface of stainless steel, preventing further oxidation and protecting the underlying metal.

Passive Layer Formation:

The key to stainless steel’s corrosion resistance lies in the formation of the passive layer. When exposed to oxygen, the chromium in stainless steel reacts with it to create a protective film of chromium oxide. This invisible layer acts as a barrier against corrosive elements, such as moisture, acids, and salts, preventing them from reaching the underlying metal and causing damage. The passive layer is self-repairing, which means that if it gets damaged or scratched, it can regenerate in the presence of oxygen.

Types of Stainless Steel:

Stainless steel is available in various grades and types, each with its unique composition and corrosion resistance properties.

Austenitic stainless steel:

This type of stainless steel, such as grades 304 and 316, is the most commonly used due to its excellent corrosion resistance in a wide range of environments, including both acidic and alkaline conditions. It has a face-centered cubic crystal structure, which contributes to its excellent formability and weldability.

Ferritic stainless steel:

Ferritic stainless steel, such as grade 430, contains a higher percentage of chromium (up to 27%) and very little or no nickel. It is known for its good resistance to stress corrosion cracking and its magnetic properties. Ferritic stainless steel is often used for applications that require high-temperature oxidation resistance.

Martensitic stainless steel:

Martensitic stainless steel, such as grade 410, has a higher carbon content and lower chromium content compared to austenitic and ferritic stainless steels. It is hardened by heat treatment and exhibits good strength, hardness, and wear resistance. Martensitic stainless steel is commonly used for blades, knives, and other applications that require high hardness and corrosion resistance.

Duplex stainless steel:

Duplex stainless steel, such as grade 2205, contains a mixture of austenite and ferrite microstructures, offering a combination of high strength and improved resistance to stress corrosion cracking. It is commonly used in applications where resistance to chloride-induced pitting and crevice corrosion is crucial, such as in marine environments and chemical processing plants.

Factors Affecting Corrosion Resistance:

Several factors influence the corrosion resistance of SS sheets, including:

Alloy Composition:

The addition of alloying elements like nickel and molybdenum enhances the corrosion resistance of stainless steel sheets, making them suitable for more aggressive environments. For example, the addition of nickel increases the stability of the passive layer, while molybdenum improves resistance to localized corrosion, such as pitting and crevice corrosion.

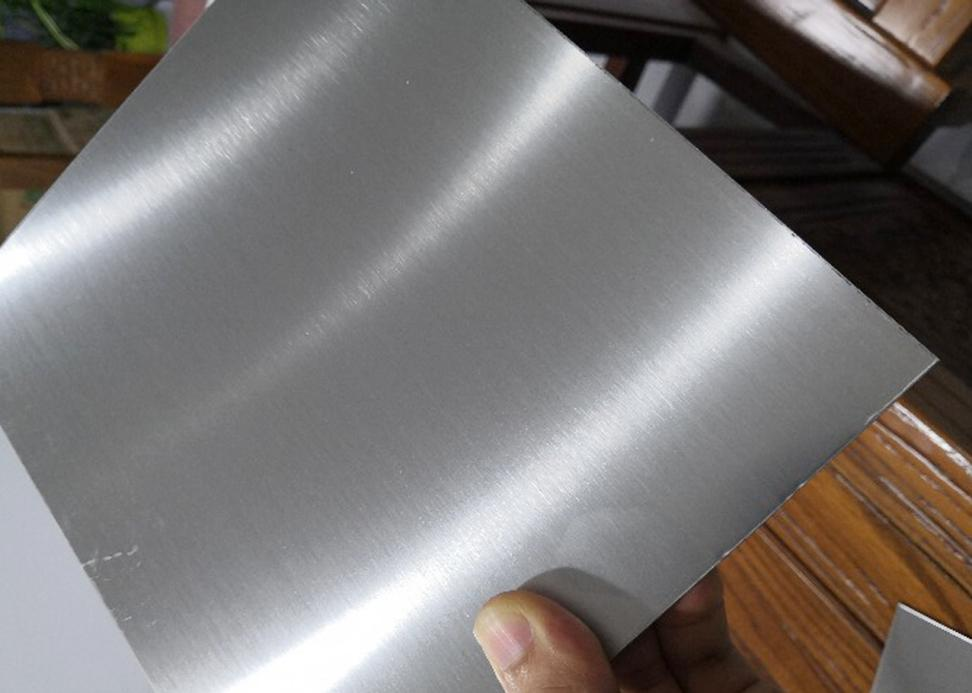

Surface Finish:

The surface finish of stainless steel sheets can significantly affect their corrosion resistance. A smooth and polished surface finish reduces the likelihood of corrosion by minimizing the potential for deposits and impurities to adhere to the metal surface. Conversely, a rough or contaminated surface can provide crevices or sites for corrosion initiation.

pH and Environment:

Stainless steel exhibits excellent resistance to corrosion in neutral and mildly acidic environments. However, it may corrode in highly acidic or alkaline conditions, so it is essential to select the appropriate grade for specific applications. For example, austenitic stainless steel, with its high chromium and nickel content, offers excellent corrosion resistance in acidic environments, making it suitable for chemical and food processing industries.

Temperature:

Elevated temperatures can affect the stability of the passive layer, potentially reducing the corrosion resistance of stainless steel. High-temperature grades, such as 310 and 316L, are specifically designed to resist corrosion in extreme temperature conditions. These grades contain additional alloying elements, such as silicon and molybdenum, to improve their high-temperature oxidation resistance.

Chloride Exposure:

Chloride ions can be particularly corrosive to stainless steel. The presence of chlorides, especially in the form of saltwater or coastal environments, can lead to pitting and crevice corrosion. It is crucial to consider the chloride concentration and exposure duration when choosing stainless steel for marine or chloride-rich environments. Duplex stainless steel, with its higher chromium and molybdenum content, provides excellent resistance to chloride-induced corrosion.

Applications of Stainless Steel Sheets:

The exceptional corrosion resistance of stainless steel sheets makes them highly sought after in various industries and applications. Some notable applications include:

Architecture and Construction:

Stainless steel plates/sheets are commonly used in building facades, roofing, structural components, and interior design elements due to their aesthetic appeal and long-lasting durability. The corrosion resistance of stainless steel ensures that these structures maintain their integrity and appearance, even in harsh environments.

Food Processing and Medical Equipment:

SS sheets are widely employed in food processing equipment, surgical instruments, and medical devices because they are hygienic, easy to clean, and resistant to corrosion caused by chemicals and organic materials. The corrosion resistance of stainless steel ensures that these critical applications meet strict hygiene and safety standards.

Chemical and Petrochemical Industries:

SS plates/sheets are suitable for storage tanks, pipelines, and equipment that handle corrosive chemicals and high-pressure environments. The corrosion resistance of stainless steel ensures that these components can withstand the corrosive nature of chemicals and prevent leaks or failures, ensuring safety and longevity.

Automotive and Transportation:

Stainless steel sheets find applications in automobile components, such as exhaust systems, fuel tanks, and decorative trims, due to their corrosion resistance and ability to withstand harsh environmental conditions. Stainless steel’s durability and resistance to corrosion contribute to the longevity and safety of automotive applications.

Energy Sector:

Stainless steel sheets are utilized in power plants, renewable energy infrastructure, and oil and gas facilities, where their corrosion resistance properties ensure long-term reliability. Whether it’s in nuclear power plants or offshore oil platforms, stainless steel keeps critical components protected from corrosion, thereby reducing maintenance costs and ensuring operational efficiency.

Household Appliances:

Stainless steel sheets are commonly used in kitchen appliances, sinks, and household fixtures due to their hygienic properties and resistance to staining and corrosion from household chemicals. The corrosion resistance of stainless steel helps maintain the aesthetic appeal and functionality of these appliances.

Conclusion:

The corrosion resistance of stainless steel sheets stems from their unique composition and the formation of a protective passive layer. Stainless steel’s exceptional resistance to corrosion makes it an ideal choice for a wide range of applications. By understanding the factors that contribute to its corrosion resistance, we can make informed decisions when selecting stainless steel sheets for various projects, ensuring long-lasting performance and durability. From architectural structures to medical equipment and from automotive components to energy infrastructure, stainless steel sheets continue to play a crucial role in numerous industries, ensuring reliability, safety, and longevity.