Introduction

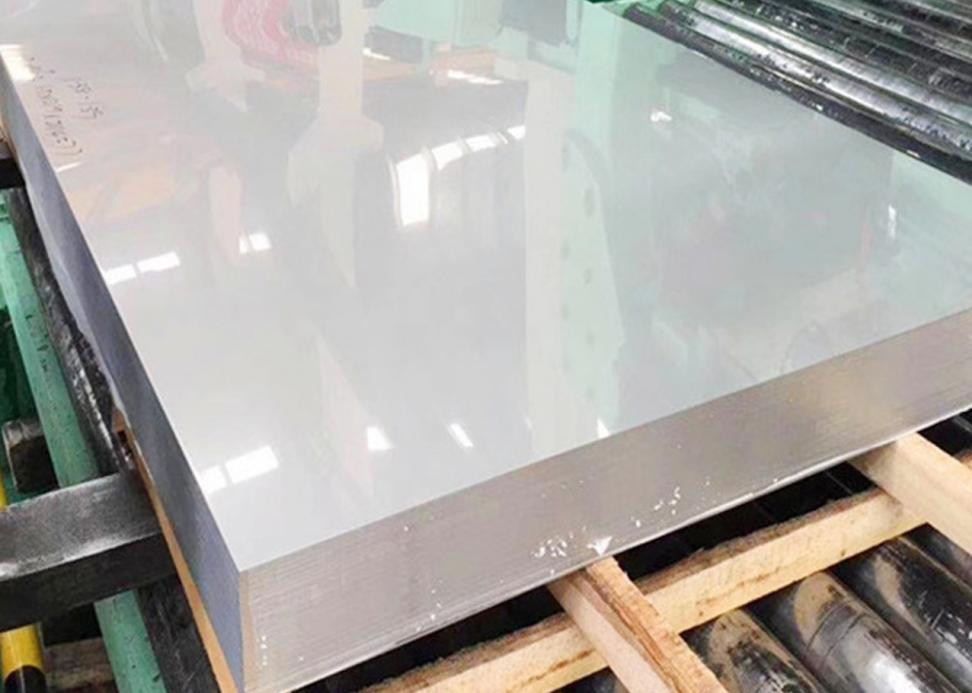

Stainless steel sheets have become an essential material in various industries, offering a multitude of benefits that make them indispensable in countless applications. With exceptional strength, durability, corrosion resistance, and aesthetic appeal, stainless steel sheets have captured the attention of industries worldwide. In this article, we will delve into the top five industries that heavily rely on stainless steel sheets for their operations. From construction to food processing, automotive to pharmaceuticals, and energy to renewable energy, these sectors have recognized the unmatched advantages that stainless steel sheets bring to their processes and products. Let’s explore the unique applications and advantages of stainless steel sheets in each of these industries, highlighting their critical role in driving innovation and growth.

Construction Industry

The construction industry stands as a prominent consumer of stainless steel sheets, relying on their exceptional properties to meet a diverse range of needs. Stainless steel sheets offer unparalleled strength, corrosion resistance, and aesthetic appeal, making them suitable for various construction applications. From structural components such as beams, columns, and roofing, to architectural features like facades, handrails, and decorative accents, stainless steel sheets provide both durability and a modern, clean appearance. Moreover, stainless steel is often employed in HVAC systems, piping, and wiring due to its ability to withstand extreme temperatures and resist moisture. The construction industry benefits greatly from the versatility and reliability of stainless steel sheets, contributing to the creation of durable and visually appealing structures.

Food and Beverage Industry

The food and beverage industry places great reliance on SS sheets due to their exceptional hygienic properties, durability, and resistance to corrosion. Stainless steel sheets are a preferred material for equipment and infrastructure within this sector, as they ensure food safety, maintain product integrity, and facilitate efficient cleaning and sanitation.

Food processing facilities

In food processing facilities, stainless steel sheets are utilized to manufacture equipment such as food preparation tables, conveyor systems, storage tanks, and mixers. These sheets offer a non-reactive surface that does not impart any taste or odor to the food, ensuring its quality remains uncompromised. Additionally, stainless steel’s anti-corrosive nature ensures that no contaminants leach into the processed food, safeguarding consumer health.

Beverage industry

Within the beverage industry, stainless steel sheets are extensively utilized for tanks, piping, and fermentation vessels during the production of beverages like beer, wine, and spirits. The sheets’ resistance to corrosion and thermal stress enables the storage and transportation of liquids without compromising their taste or quality.

Furthermore, stainless steel sheets are essential for the construction of commercial kitchens and food service establishments. They are utilized to fabricate work tables, sinks, countertops, shelves, and ventilation systems. These sheets are easy to clean, resistant to stains and bacterial growth, and can withstand high temperatures, making them ideal for food preparation and storage areas.

Overall, the food and beverage industry heavily relies on stainless steel sheets for their hygienic properties, durability, and corrosion resistance, ensuring the production and delivery of safe and high-quality food and beverages to consumers.

Automotive Industry

The automotive industry is among the leading sectors that heavily rely on stainless steel sheets due to their exceptional properties and diverse applications. Stainless steel sheets play a crucial role in various aspects of automotive manufacturing, enhancing performance, durability, and aesthetics.

Body and Chassis:

Stainless steel sheets are used for body panels and chassis components, offering excellent strength and corrosion resistance. These sheets contribute to the structural integrity of vehicles while ensuring longevity and protection against rust.

Exhaust Systems:

Stainless steel sheets are a preferred choice for manufacturing exhaust systems due to their high-temperature resistance and resistance to corrosion caused by exhaust gases and moisture. These sheets enable the production of durable and efficient exhaust components.

Trim and Accents:

Stainless sheets are utilized for exterior trim and accent pieces in vehicles. Their smooth finish, durability, and resistance to weathering make them ideal for enhancing the aesthetics of vehicles while also providing protection against impact and scratches.

Fuel Tanks and Fuel System Components:

Stainless steel sheets are commonly used in the fabrication of fuel tanks and components within the fuel system. Their corrosion resistance ensures the integrity and safety of the fuel system, preventing leakage and extending the lifespan of these crucial automotive parts.

Fasteners and Hardware:

Stainless steel sheets are employed in the manufacturing of nuts, bolts, screws, and other fasteners, providing excellent strength, resistance to corrosion, and long-term reliability. These components play a vital role in securing various parts of the vehicle together.

Overall, the automotive industry relies on stainless steel sheets for applications ranging from the structural integrity of vehicles to exhaust systems, trim, fuel components, and fasteners. The use of stainless steel sheets in these critical areas contributes to the safety, performance, and longevity of automobiles.

Pharmaceutical Industry

The pharmaceutical industry is one of the key sectors that heavily depend on stainless steel sheets for various critical applications. Stainless steel sheets offer exceptional cleanliness, chemical resistance, and durability, making them essential in ensuring the safety, quality, and integrity of pharmaceutical products.

Manufacturing Equipment:

Stainless steel sheets are extensively used in the construction of pharmaceutical manufacturing equipment such as reactors, tanks, mixers, and storage vessels. They provide a non-reactive surface, preventing contamination and maintaining the purity of the pharmaceutical compounds during processing, storage, and transportation.

Cleanrooms and Sterile Environments:

Stainless steel sheets are an integral component in the construction of cleanrooms and sterile environments. These highly controlled environments require materials that are easy to clean, resistant to microbial growth, and can withstand stringent sterilization procedures. Stainless steel sheets meet these requirements and provide a hygienic and sterile environment for pharmaceutical production and research.

Laboratory Furniture and Workstations:

Stainless steel sheets are used in the fabrication of laboratory furniture, work surfaces, and countertops. Their resistance to chemicals, stains, and corrosion makes them suitable for handling pharmaceutical samples, reagents, and equipment, ensuring a safe and contamination-free laboratory environment.

Packaging and Storage Systems:

Stainless steel sheets are utilized in the manufacturing of pharmaceutical packaging and storage systems, such as shelves, racks, and containers. These sheets offer optimal hygiene levels, preventing product degradation, and maintaining the integrity of pharmaceuticals during their shelf life.

HVAC Systems:

Stainless steel sheets are crucial in the construction of HVAC (Heating, Ventilation, and Air Conditioning) systems for pharmaceutical facilities. They provide corrosion resistance, ensuring clean and uncontaminated air circulation within the premises, thus reducing the risk of airborne pollutants and maintaining a controlled environment.

In essence, the pharmaceutical industry relies on stainless steel sheets for a range of applications, including manufacturing equipment, cleanrooms, laboratory furniture, packaging and storage systems, and HVAC systems. The use of stainless steel sheets ensures compliance with strict regulatory requirements and guarantees the safety, purity, and efficacy of pharmaceutical products.

Energy and Renewable Energy Sector

The energy and renewable energy sector heavily relies on stainless steel sheets for various critical applications. Stainless steel sheets offer excellent corrosion resistance, high strength-to-weight ratio, and durability, making them essential in ensuring the efficiency, reliability, and longevity of energy systems.

Power Generation:

Stainless steel sheets are widely used in power generation facilities, including nuclear power plants, coal-fired power plants, and natural gas power plants. They are used for components such as heat exchangers, turbines, boilers, valves, and piping systems due to their resistance to high temperatures, pressure, and corrosion.

Oil and Gas Industry:

The oil and gas industry extensively employs stainless steel sheets for drilling, extraction, and refining operations. These sheets are used in offshore platforms, pipelines, storage tanks, and equipment that require resistance to corrosive environments and high mechanical stress.

Solar Energy:

Stainless steel sheets play a crucial role in the manufacturing of solar energy equipment. They are used for solar water heaters, heat exchangers, and mounting structures for solar panels due to their weather resistance and durability, ensuring the long-term performance of solar energy systems.

Wind Energy:

Stainless steel sheets are essential in the production of wind turbines and wind energy infrastructure. They are used for tower structures, mounting systems, and foundation components due to their high strength, corrosion resistance, and ability to withstand extreme weather conditions.

Battery Technology:

Stainless steel sheets are utilized in the production of batteries and energy storage systems. They are used for battery enclosures, casings, and components due to their corrosion resistance, mechanical strength, and ability to safely contain hazardous materials.

In summary, the energy and renewable energy sector relies on stainless steel sheets for power generation, oil and gas operations, solar energy systems, wind turbines, and battery technology. The use of stainless steel sheets in these industries ensures the durability, safety, and efficiency of energy production and storage, contributing to the sustainability and advancement of the sector.

Conclusion

Stainless steel sheets are essential components in various industries due to their remarkable properties and versatility. The construction, food and beverage, automotive, pharmaceutical, and energy sectors greatly rely on stainless steel sheets for their distinct applications. Whether it’s providing structural support, ensuring hygienic manufacturing processes, enhancing automotive efficiency, or powering renewable energy systems, stainless steel sheets continue to play a crucial role in driving progress and innovation across multiple industries. With ongoing advancements in stainless steel technology, these industries are likely to deepen their reliance on this remarkable material for years to come, further pushing the boundaries of what is possible.